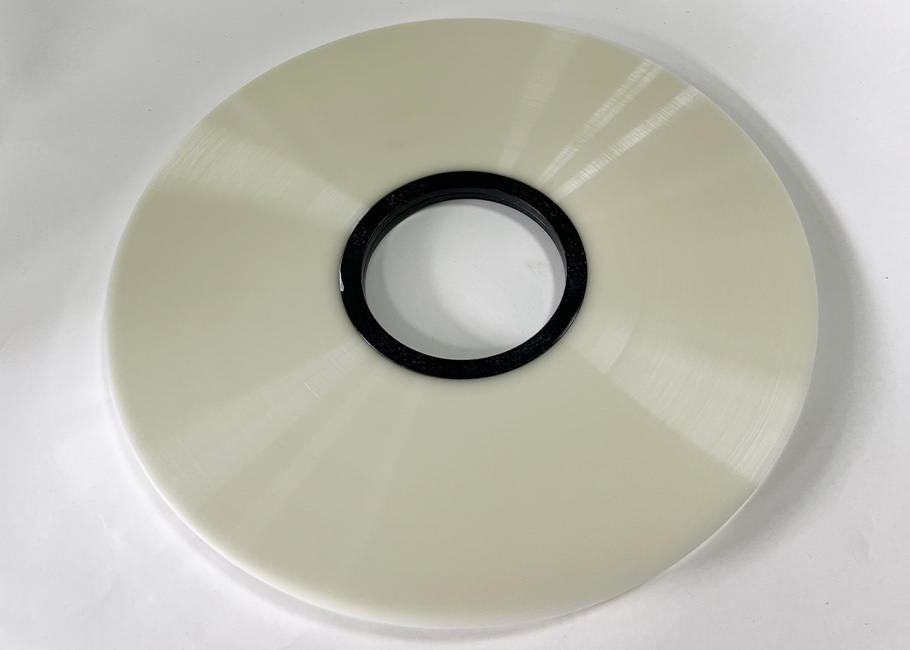

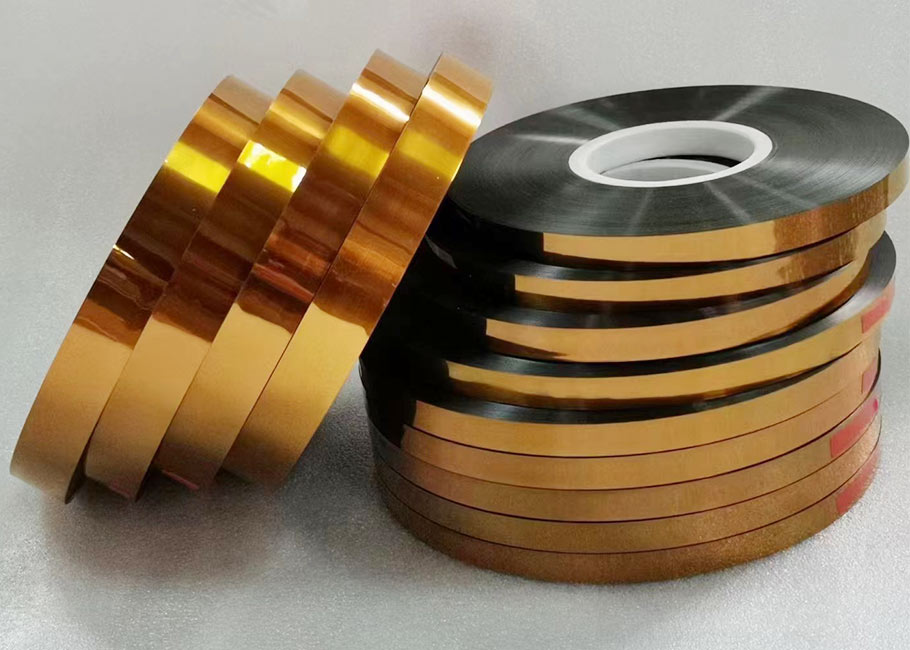

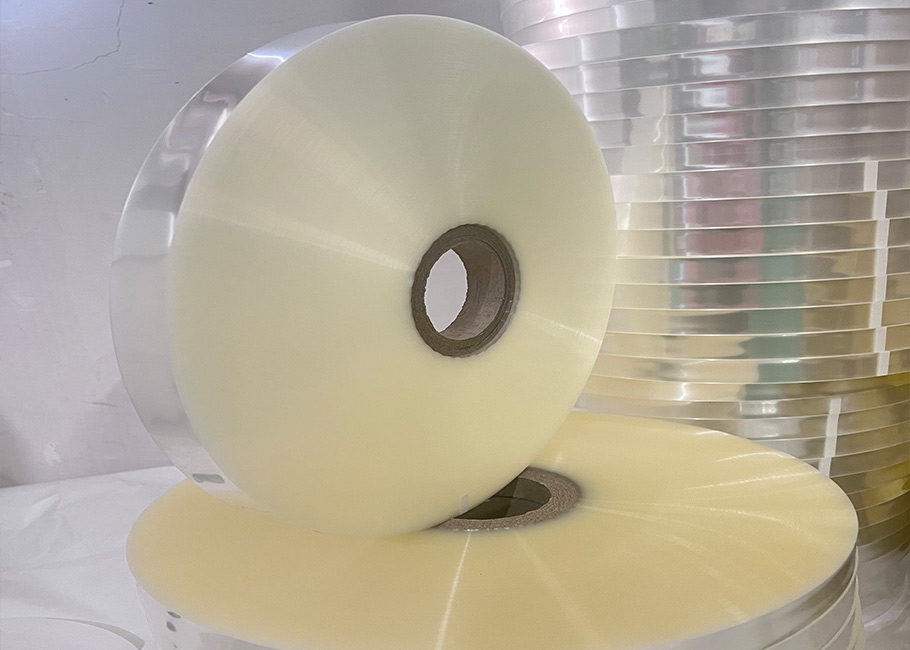

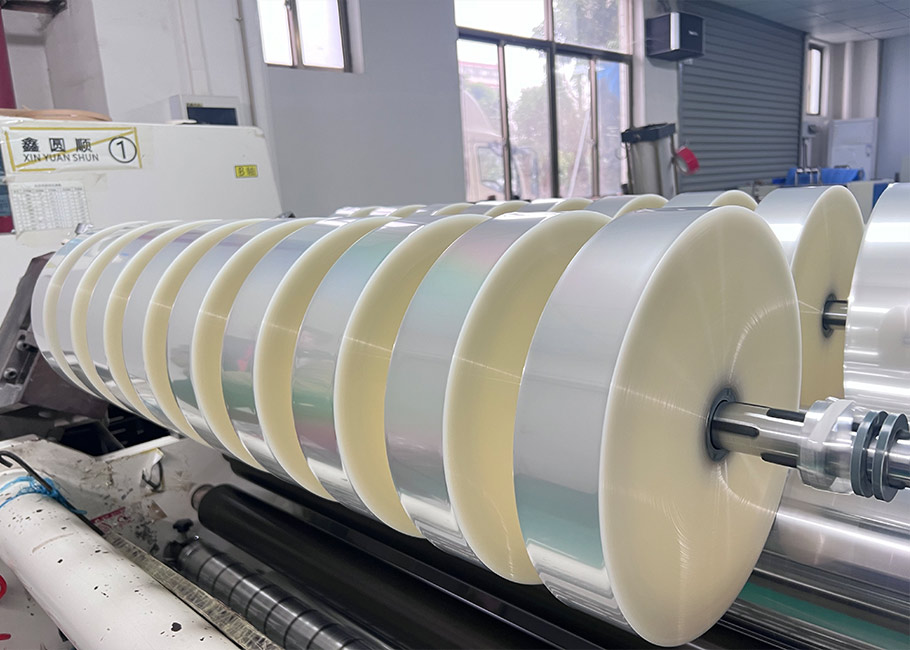

Eco-Friendly Opp Film Packaging

- Product Information

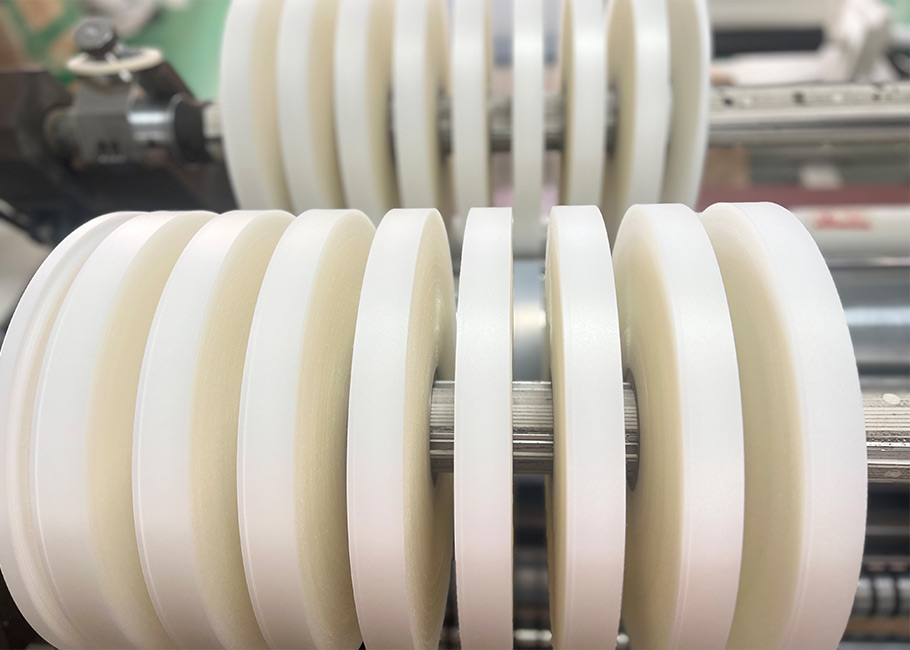

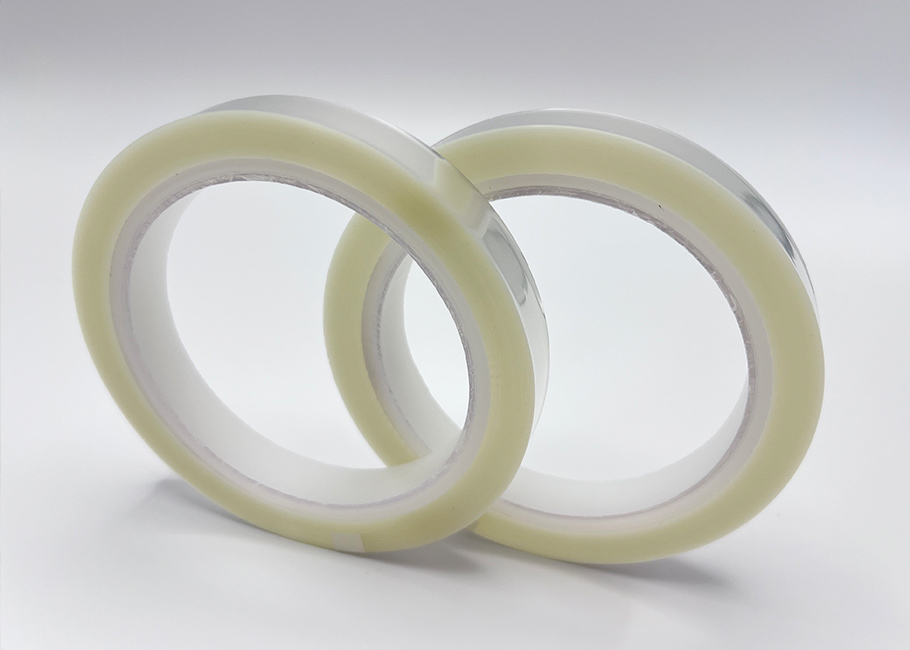

OPP Film Packaging is a packaging form that uses oriented polypropylene (OPP) film as the core material. OPP film is a polypropylene film that has been processed by a biaxial stretching process, which gives the film unique properties. This form of packaging is widely used in daily life. It can not only effectively protect the product, but also provide excellent display effects.

Opp Film Packaging Parameters:

| Material: | OPP |

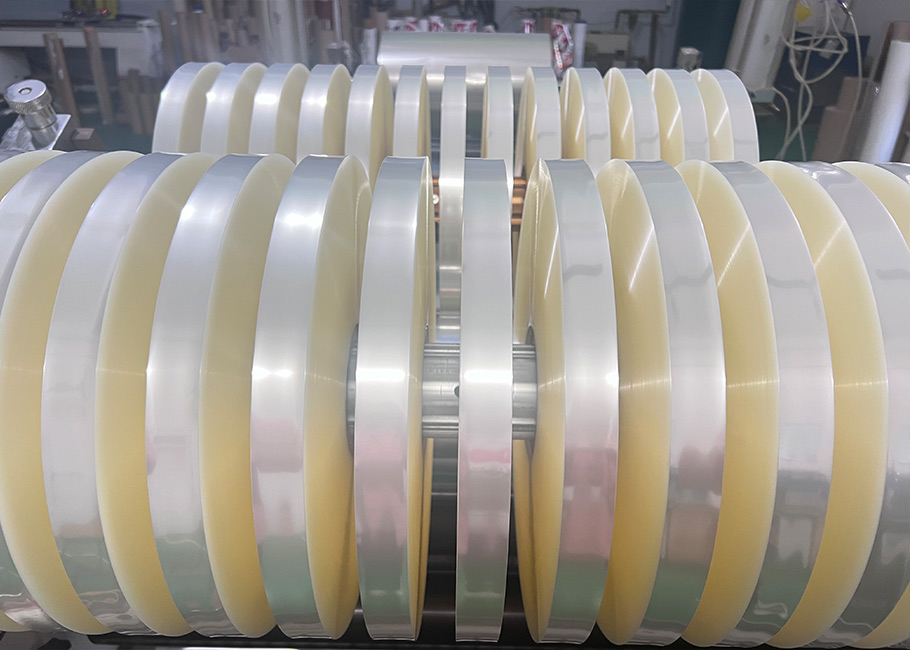

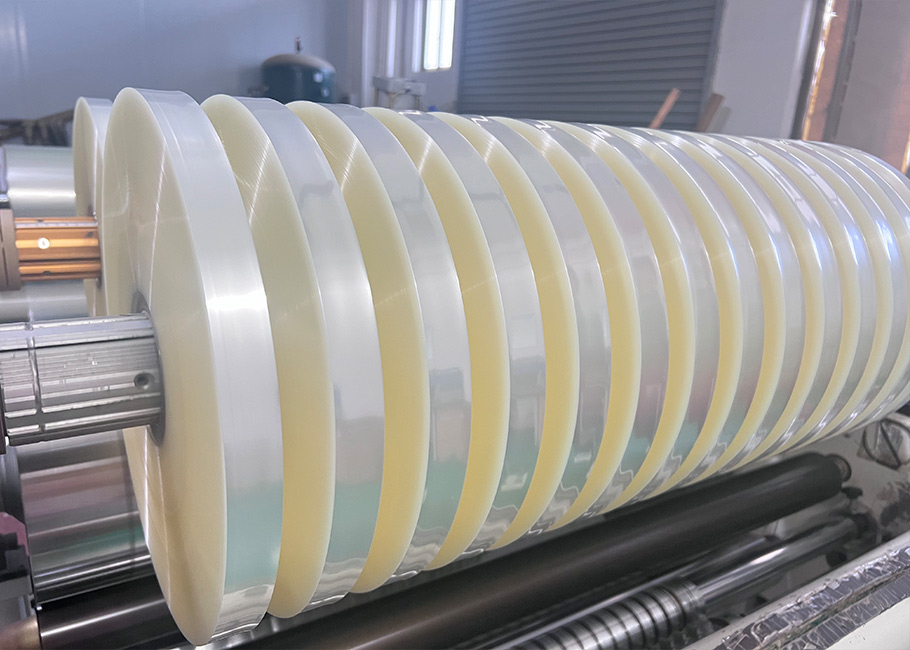

| Dimensions: | Customizable Material Width And Thickness According To Customer Requirements |

| OEM: | OEM/ODM Available |

| Packaging: | Carton |

Opp Film Packaging Features:

High transparency:

OPP film has extremely high transparency. After professional testing, its light transmittance can be as high as 92% or more (measured by a light transmittance tester that meets national standards). Such high transparency allows the product in the package to be presented clearly without any hindrance. Taking cosmetics as an example, consumers can directly see the color of lipstick, the delicate texture of powder and other details without opening the package. This not only greatly facilitates consumers to have a preliminary understanding of the product before purchase, but also significantly improves the display effect of the product, increases the attractiveness of the product on the shelf, and thus improves the market competitiveness of the product. The high transparency makes OPP Film Packaging stand out among many packaging materials and become an ideal choice for displaying products. Good gloss: OPP film surface has excellent gloss. Through standard gloss meter measurement, its gloss value can reach more than 85%. This high gloss gives the packaging a high-end and exquisite visual experience, greatly improving the overall image and quality of the product. In the field of household goods packaging, such as the packaging of exquisite ceramic ornaments, high-gloss OPP film packaging can make the product look more luxurious and high-end. When consumers see this type of packaged product on the shelf, they are more likely to be attracted to it, increasing the possibility of purchase. The high-quality performance of glossiness enables OPP Film Packaging to create a high-quality brand image for the product.

Excellent tensile strength:

OPP film has excellent tensile strength after biaxial stretching. The longitudinal tensile strength can reach 120-160MPa, and the transverse tensile strength can reach 160-220MPa (determined according to the national standard tensile test method). This means that during the packaging process, OPP film can withstand large tensile forces without breaking. In stationery packaging, when packaging a stack of thicker books or a large amount of paper, OPP film can wrap the items stably with its high tensile strength without being damaged by the weight and tension of the paper. This reliable tensile performance ensures the integrity of the packaging during various complex operations and transportation processes.

Excellent stiffness:

OPP film has good stiffness, and its stiffness value can reach a high level under certain conditions when measured by a professional stiffness tester. This stiffness allows the packaging to maintain a stable shape after forming. When packaging irregularly shaped daily necessities, such as some special-shaped plastic products, OPP film packaging with good stiffness can fit the product contour closely and maintain the three-dimensional sense of the packaging. This not only makes the packaging more beautiful, but also facilitates the stacking and display of products on shelves, improves space utilization, and better protects the products from being squeezed and deformed during transportation and storage.

Stable dimensional performance:

OPP film has extremely small dimensional change rate in environments with temperature and humidity changes. Under the conditions of temperature change range of - 25℃ - 65℃ and humidity change range of 15% - 85%, the dimensional change rate of its length and width does not exceed ±0.8% (determined according to the national standard dimensional change rate test method). This stable dimensional performance ensures the adaptability of packaging in different environments. During long-distance transportation, goods may experience various complex temperature and humidity conditions. OPP film packaging can always maintain stable size, provide continuous and reliable protection for products, and avoid product damage due to packaging deformation.

Good moisture resistance:

OPP film has excellent barrier properties to water vapor and low water vapor permeability. Under standard test conditions (temperature 38℃, relative humidity 90%), the water vapor transmission rate of OPP film can be less than 8g/(m²·24h) (measured by a professional water vapor transmission rate tester). This feature enables it to effectively block external moisture from entering the interior of the package and protect the product from moisture. For some daily necessities that are extremely sensitive to humidity, such as electronic equipment accessories, dry food, etc., the moisture-proof performance of OPP film is crucial to ensure that the quality and performance of the product are not damaged by the humid environment and extend the shelf life of the product.

Chemical stability:

OPP film has good chemical stability and can resist the erosion of a variety of chemicals. In common acid, alkali, organic solvent and other environments, OPP film will not undergo obvious chemical reactions and performance changes. For example, when exposed to cosmetics or cleaning products containing a certain concentration of alcohol, OPP film will not deteriorate or crack due to the erosion of chemicals. This chemical stability enables OPP Film Packaging to be safely used for the packaging of various products of different chemical properties, ensuring the integrity and reliability of the packaging during product use and storage.

Environmentally friendly and recyclable:

OPP film is an environmentally friendly material with the characteristics of being recyclable. After professional processing, the recycled OPP film can be remade into new film or other plastic products. According to relevant research data, the performance of recycled OPP film is similar to that of original film, and it can significantly reduce environmental pollution and resource consumption. In the current global context of advocating sustainable development and environmental protection, the environmental protection characteristics of OPP Film Packaging meet the requirements of the times, which not only helps enterprises achieve environmental protection goals, but also meets consumers' demand for environmentally friendly products and enhances the social image of enterprises.

Opp Film Packaging Application:

Cosmetics packaging

The cosmetics industry has extremely strict requirements for packaging. Not only does it require the packaging to protect the product, but it also needs to have an excellent display effect. The high transparency and high gloss of OPP Film Packaging can perfectly display the appearance and color of cosmetics. For example, for lipstick, consumers can clearly see whether the color of the lipstick meets their preferences and whether the texture of the lipstick is delicate through the transparent OPP film packaging. For powder, the high transparency of the packaging allows consumers to intuitively see the flatness and color of the powder. This display effect can attract consumers' attention and increase the attractiveness of the product on the shelf. Market research shows that the sales conversion rate of cosmetics using OPP Film Packaging is about 22% higher than that of cosmetics with ordinary packaging, which effectively improves the market competitiveness of the product.

Stationery packaging

There are many types of stationery products, including notebooks, pens, folders, etc. OPP Film Packaging can be customized according to different stationery products to provide suitable packaging size and thickness. Its excellent tensile strength and stiffness make the packaging less likely to be damaged during transportation and storage. When packaging a stack of thick notebooks, OPP film can withstand the weight and tension of the notebooks and maintain the integrity of the packaging. At the same time, the transparent packaging allows consumers to intuitively see the style, color and pattern of the stationery, making it easier to choose. In some large stationery stores, the sales of stationery products using OPP Film Packaging are about 18% higher than those not using it, which improves the sales performance of the products.

Household goods packaging

Household goods such as ceramic ornaments, glassware, plastic products, etc. require packaging to provide good protection and display effects. The high transparency and glossiness of OPP Film Packaging can enhance the grade of household goods and make them more conspicuous on the shelves. For ceramic ornaments, high-gloss packaging can set off the smooth texture and exquisite patterns of ceramics, attracting the attention of consumers. Its stable dimensional performance and tensile strength ensure that the packaging will not deform or break during handling and storage, effectively protecting household goods. Relevant data show that the breakage rate of household goods using OPP Film Packaging during transportation is about 35% lower than that of ordinary packaging, reducing the loss of enterprises.

Food packaging (non-direct contact)

For some dry foods, such as biscuits and nuts, OPP Film Packaging can be used as outer packaging. Its moisture-proof performance can prevent food from getting damp and softening, and keep the food crispy. Under standard humidity conditions, OPP film can effectively block external moisture, so that the food maintains good quality during the shelf life. At the same time, transparent packaging allows consumers to see the appearance and color of the food, increasing their desire to buy. In the food retail market, the sales of dry foods using OPP Film Packaging have increased to a certain extent, about 12%, which helps food companies increase their market share.

Electronic product accessories packaging

Electronic product accessories such as chargers, data cables, headphones, etc. have high requirements for packaging moisture-proof and protective performance. The moisture-proof performance of OPP Film Packaging can prevent electronic product accessories from being damaged by moisture and ensure their stable electrical performance. Its excellent tensile strength and stiffness can ensure that the packaging will not be damaged by external forces during transportation and protect the integrity of the accessories. Moreover, transparent packaging makes it convenient for consumers to check the appearance and model of accessories, making it easier to choose. In some electronic product accessories sales channels, the return rate of accessories using OPP Film Packaging is about 13% lower than that of ordinary packaging, which improves customer satisfaction.

Toy Packaging

Toys come in many types and shapes, and OPP Film Packaging can be customized according to the shape and size of the toys. Its high transparency can show the appearance and color of the toys and attract children's attention. For example, for some colorful plastic toys, transparent OPP film packaging can make the colors of the toys more vivid. At the same time, the tensile strength and stiffness of the OPP film can ensure that the packaging remains intact during the transportation and display of the toys, preventing the toys from being damaged. In the toy market, the sales volume of toys using OPP Film Packaging has increased significantly compared with toys with ordinary packaging, with a growth rate of about 15%, which has improved the economic benefits of toy companies.

Opp Film Packaging Maintenance:

Avoid direct sunlight

OPP film will age and discolor under long-term direct sunlight, which seriously affects the appearance and performance of the packaging. The ultraviolet rays in the sun will destroy the molecular structure of the film, resulting in a decrease in its tensile strength and transparency. Experiments show that after 100 hours of continuous direct sunlight, the tensile strength of OPP film will decrease by more than 35%, and the transparency will also be significantly reduced to less than 70%. Therefore, when storing and transporting OPP Film Packaging products, direct sunlight should be avoided as much as possible. The packaged products can be stored in a cool and ventilated place, or shaded with sunshade materials, such as building a sunshade or covering it with a sunshade cloth.

Control the humidity of the storage environment

Although OPP film has good moisture resistance, its performance may still be affected if it is stored in an environment with too high or too low humidity. Generally speaking, the humidity of the storage environment should be controlled between 45% and 55%. Excessive humidity may cause moisture to be adsorbed on the surface of the film, affecting its stiffness and viscosity (if it is coated with glue). When the humidity exceeds 60%, the film may become soft, the stiffness decreases by about 20%, and it is easy to stick. Too low humidity may make the film fragile and reduce its tensile strength. In an environment with a humidity of less than 30%, the tensile strength of the film may decrease by about 15%. Humidity regulating equipment can be used to control the humidity of the storage environment, such as a dehumidifier or humidifier, to ensure that the humidity is within an appropriate range.

Prevent scratches from sharp objects

The surface of OPP film is relatively smooth, but it is easy to be scratched by sharp objects. During packaging, transportation and storage, special attention should be paid to avoid contact with sharp objects. For example, during handling, be careful to avoid friction between the film and objects such as knives and metal corners. Once the film is scratched, it will not only affect the appearance of the packaging, but also reduce its protective performance. Experiments show that the tensile strength of OPP film scratched by sharp objects will decrease by more than 55% at the scratched part, making the packaging more likely to break when subjected to external force. If a sharp object accidentally approaches, protective measures should be taken in time, such as using a protective pad or adjusting the position of the items.

Check the integrity of the package regularly

For packaged products, check the integrity of the package regularly. Check for damage, air leakage (if there is air cushion packaging), etc. It is recommended to conduct a comprehensive inspection of the packaged products every two weeks. If there is a problem with the packaging, take timely measures to repair or replace the packaging. Regular inspections can detect potential problems in time and prevent the product from being damaged during transportation and storage. For example, if the packaging is found to have minor damage, it should be repaired with tape in time to prevent the damage from expanding and causing damage to the product.

Avoid contact with chemicals

Although OPP film has good chemical stability, some strong acids, strong alkalis or organic solvents may still damage it. During storage and use, avoid contact between OPP Film Packaging and these chemicals. If accidentally contacted, it should be rinsed with plenty of clean water in time, and appropriate treatment measures should be taken according to the properties of the chemical. For example, after contact with some organic solvents, OPP film may dissolve, deform, etc., affecting the use of the packaging. If it comes into contact with strong acids, the surface of the film may be corroded, resulting in a decrease in tensile strength of more than 40%, so such contact must be strictly avoided.

Reasonable stacking

When storing and transporting OPP Film Packaging products, they should be stacked reasonably. Avoid stacking too high or too heavy to avoid crushing the bottom packaging. You can choose the appropriate stacking method and number of layers according to the size and weight of the packaging. Generally speaking, the stacking height should not exceed 1.8 meters, and the stacking should be neat to prevent tilting and collapse. Reasonable stacking methods can reduce damage to the packaging during storage and transportation. If the stacking is improper, the bottom packaging may be deformed due to excessive pressure, affecting the protection effect of the product.

Pay attention to temperature changes

OPP film may change size and fluctuate in performance under rapid temperature changes. Therefore, during storage and transportation, try to avoid rapid temperature changes. For example, do not suddenly transfer the packaged product from a cold environment to a high temperature environment, or vice versa. The packaged product can be stored in an environment with a relatively stable temperature, and the temperature change range can be controlled within ±8℃. This can ensure the stable performance of OPP Film Packaging. If the temperature changes drastically, the film may shrink or expand, causing the packaging to deform, affecting the display and protection effect of the product.

Clean the packaging surface

If the surface of OPP Film Packaging is stained with dust, stains, etc., it should be cleaned in time. You can use a soft damp cloth to gently wipe it, and avoid using rough cloth or brushes to avoid scratching the surface of the film. After cleaning, use a dry cloth to wipe the surface moisture to prevent water stains from remaining. Keeping the packaging surface clean can not only improve the appearance of the product, but also prevent stains from affecting the performance of the film. If stains remain for a long time, it may corrode the surface of the film, reducing its glossiness and chemical stability.

Opp Film Packaging FAQs:

What material does your Opp Film Packaging comprise of?

The core substance used in making the Opp Film Packaging is Oriented Polypropylene which is known for being a reliable and multifaceted thermoplastic polymer that is clear, robust, and moisture resistant. For these attributes, it is an appropriate answer for a variety of packaging purposes that include but not limited to cosmetics, food items, stationery, and home accessories.

Is it possible to order Opp Film Packaging of specific sizes or thickness?

Absolutely, we have the capability to manufacture and supply Opp Film Packaging that is tailored according to your specifications. You might choose the film width, film thickness, film length etc in order to satisfy your specific packaging requirements.

Where can we use your Opp Film Packaging?

The use of our products is pretty much universal that is the Opp Film Packaging has a wide application in many different industries such as: beauty, cosmetics, plastic, personal care products, beautifying products, lotions and perfumes packaging.