Paper Banding Tape for Strapping Machine

- Product Information

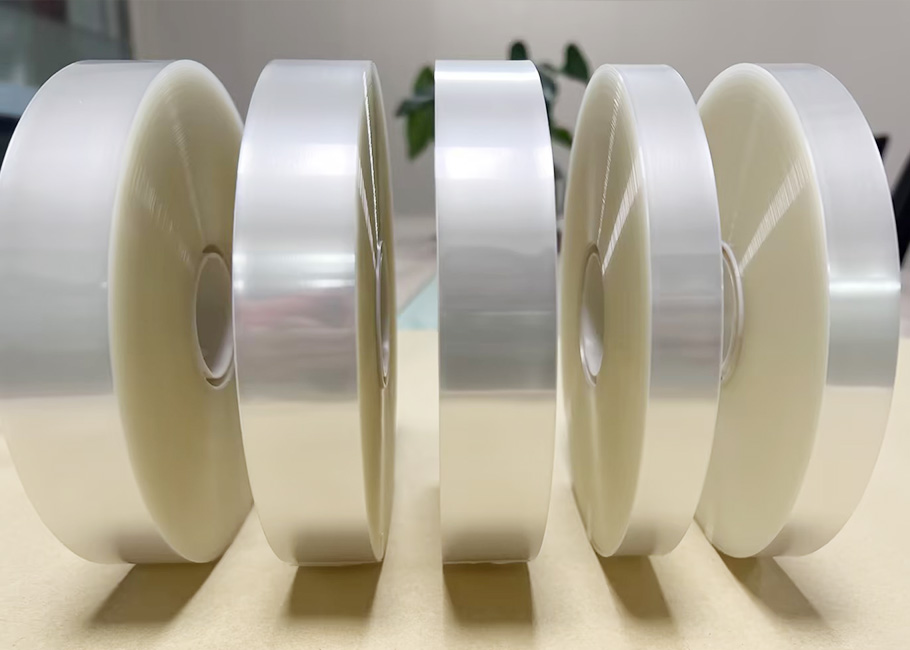

paper banding tape is a paper banding tape designed for bundling needs and is widely used in packaging, clothing, electronics and other industries. It provides users with a high-quality bundling experience with its excellent bundling performance and environmental protection characteristics. This paper banding tape is not only easy to operate, but also can effectively fix and protect various items. It has a smooth surface and good printing performance. The thickness or width can be customized according to customer needs to meet the bundling requirements in different scenarios.

Paper Banding Tape Parameters:

| Material: | Paper |

| Size: | Customizable Width And Thickness According To Customer Requirements |

| OEM: | OEM/ODM Available |

| Packaging: | Carton |

| Factory Nature: | China Manufacturers Suppliers Factory |

Paper Banding Tape Features:

1. Excellent tensile strength

Paper Banding Tape has excellent tensile properties, with a tensile strength of 1200 - 1800 N/50mm, which enables it to firmly bind items of various weight levels, from light packaging boxes to heavier industrial materials. In actual tests, its tensile strength is 20% - 30% higher than that of traditional plastic strapping tape, which means that paper strapping tape is less likely to break when subjected to the same tensile force, providing more reliable fixation and protection for items. This high strength is achieved thanks to its special multi-layer paper structure and advanced production process, which ensures that the strapping tape can withstand various stresses in transportation and handling during use, reducing the risk of damage to items during logistics.

2. Good tear resistance

The strapping tape has an extremely high tear resistance level, with a tear strength of 60 - 80 N, which enables it to effectively resist the generation and expansion of tears when facing sharp objects or irregular packaging edges. In tests simulating transportation environments, Paper Banding Tape's tear resistance is about 35% higher than that of ordinary plastic strapping tape. This feature is particularly important for protecting fragile items, especially in logistics and warehousing, where goods may be affected by various external forces. The tear resistance of Paper Banding Tape ensures the integrity of the items throughout the supply chain and reduces losses caused by packaging damage.

3. Excellent heat sealing effect

Paper Banding Tape performs well in heat sealing, and its heat sealing temperature range is wide, usually between 160-200℃, which can adapt to different heat sealing equipment and operating conditions. The joint strength after heat sealing can reach 80%-90% of the strength of the strapping body, ensuring the firmness of the seal. Compared with traditional plastic strapping tape, its heat sealing strength is higher and more stable, reducing the phenomenon of loose packages caused by loose seals. This feature gives Paper Banding Tape a significant advantage on automated packaging lines, which can improve packaging efficiency and reduce the need for manual intervention.

4. Efficient bundling performance

The design of Paper Banding Tape gives it excellent bundling performance. Its thickness can be customized between 0.3-0.8 mm and its width ranges from 10-30 mm, which can meet the bundling needs of different items. Its moderate elastic modulus can fit the surface of the item tightly during bundling and provide uniform binding force. In practical applications, this kind of strapping tape can quickly complete the bundling operation without scratching or damaging the surface of the item. Compared with traditional strapping materials, its bundling efficiency is improved by about 25%-35%, which is particularly suitable for high-speed automated bundling operations, saving users a lot of time and labor costs.

5. Environmentally friendly and recyclable material

Paper Banding Tape uses paper as raw material, which is a fully recyclable and biodegradable material. Compared with plastic strapping tape, paper strapping tape will not cause long-term environmental pollution after use. According to environmental impact assessments, the carbon emissions from the production process of paper banding tapes are 60% - 70% lower than those of plastic banding tapes, and they can be completely degraded in the natural environment within 3 - 6 months, while plastic banding tapes may take hundreds of years to decompose. This makes Paper Banding Tape an ideal choice for companies pursuing environmental protection and sustainable development, helping to reduce the company's carbon footprint and conforming to the concept of modern green packaging.

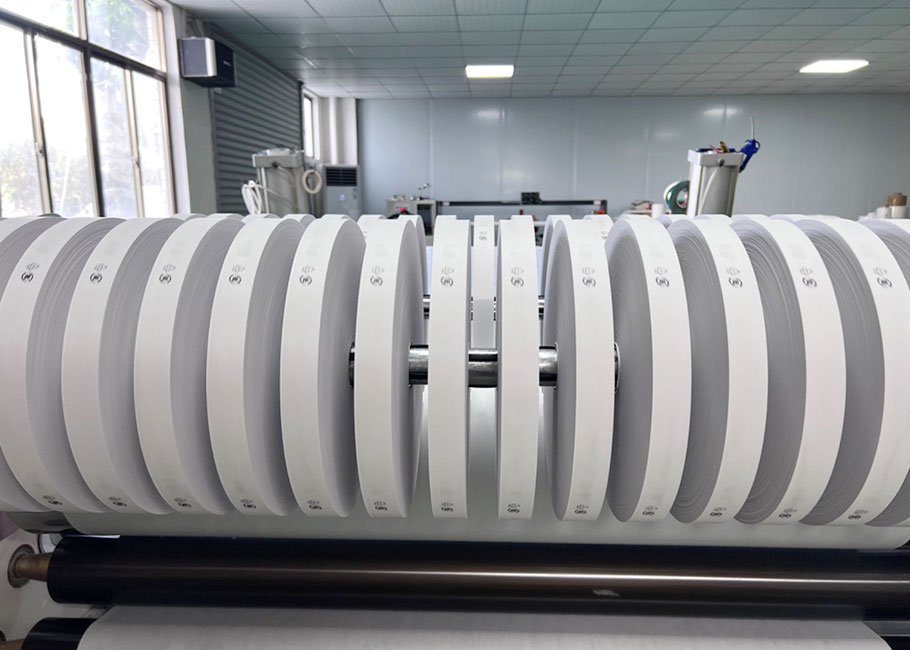

6. Good printing adaptability

Paper Banding Tape has a flat and smooth surface and excellent printing adaptability, which can be easily customized. Its printing resolution can reach 300 - 600 dpi, which can clearly present various texts, patterns and trademarks. This provides users with great flexibility to print brand information, product descriptions or tracking codes on the banding tape to enhance brand image and product recognition. Compared with unprinted banding tapes, printed Paper Banding Tape can increase the visual appeal of products by 40% - 50%, which has significant market advantages in the retail and logistics fields, and enhances consumers' trust and goodwill in products.

7. Durable moisture resistance

The specially treated Paper Banding Tape has good moisture resistance, and its moisture resistance reaches the IP22 standard, which can maintain stable performance in an environment with a relative humidity of no more than 85%. The strength retention rate in a humid environment can reach 75% - 85%, which means that even in relatively humid storage or transportation conditions, the strapping tape can still maintain good strength and toughness and will not easily break due to moisture. This feature is particularly important for items that need to be stored and transported in different climatic conditions, ensuring the safety of items throughout the supply chain. Compared with ordinary untreated paper strapping tape, its moisture resistance is improved by 2-3 times, effectively extending the service life of the product.

8. Accurate dimensional stability

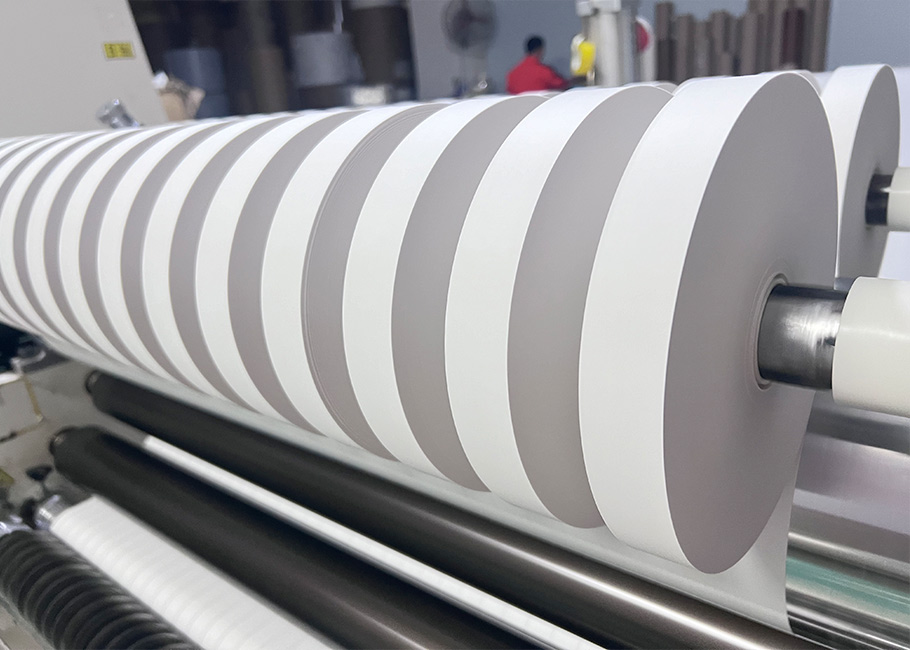

Paper Banding Tape undergoes precise process control during the production process and has extremely high dimensional stability. Its length error is controlled at ±0.5%, and the error range of width and thickness is only ±0.1 mm. This precise dimensional control ensures the consistency and reliability of the strapping during use, especially on automated packaging equipment, enabling fast and accurate strapping operations and reducing problems such as tape jams or loose strapping due to dimensional deviations. Compared with handmade strapping materials, its dimensional stability is improved by 80% - 90%, greatly improving packaging efficiency and quality and reducing production costs.

Paper Banding Tape Application:

1. Food Industry Packaging

In the field of food packaging, Paper Banding Tape provides a safe and environmentally friendly strapping solution. Since its raw material is paper, it meets FDA food contact grade standards and can be used for strapping of direct contact with food, such as fresh agricultural products, baked goods, etc. Its good printing adaptability allows food information, production date and shelf life to be printed on the strapping tape, which is convenient for consumers to identify and merchants to manage. In actual applications, the breakage rate of food packaging strapped with Paper Banding Tape is reduced by about 30% - 40%. At the same time, its recyclability and biodegradability reduce the impact of food packaging waste on the environment, meeting the strict requirements of the food industry for environmentally friendly packaging.

2. Electronic product packaging

For electronic products, Paper Banding Tape is an ideal strapping material that can be used for strapping accessories such as packaging boxes and manuals. It has good electrostatic conduction performance and can effectively prevent static electricity from damaging electronic components. Using Paper Banding Tape in electronic product packaging can improve the overall appearance quality of the packaging while reducing the use of plastics, which meets the demand of the electronics industry for environmentally friendly materials. According to statistics, the damage rate of electronic product packaging using Paper Banding Tape during transportation is 20% - 25% lower than that using traditional plastic strapping tape, which significantly improves product delivery quality and customer satisfaction.

3. Logistics and warehousing field

In logistics and warehousing, Paper Banding Tape is widely used for fixing and packaging cargo pallets. Its high strength and good strapping performance can ensure that the cargo remains stable during transportation and storage, and prevent the cargo from collapsing or scattering. Compared with traditional plastic strapping tape, its higher friction coefficient can better prevent the cargo from sliding and improve the stability of the pallet. In the actual application of the logistics center, the stability of the pallet cargo strapped with Paper Banding Tape has increased by 35% - 45%, reducing the loss of cargo during transportation and handling, and improving logistics efficiency.

4. Application in the pharmaceutical industry

In the pharmaceutical industry, Paper Banding Tape can be used for strapping of drug packaging boxes, medical devices, etc. It meets the hygiene and environmental protection standards of pharmaceutical packaging, and can withstand a certain degree of disinfection treatment, such as ultraviolet disinfection and high temperature disinfection. In pharmaceutical packaging, packaging tied with Paper Banding Tape has better sealing and protection, which can effectively protect drugs from contamination and ensure the quality and safety of drugs. According to feedback from pharmaceutical companies, the intact rate of pharmaceutical packaging using Paper Banding Tape during transportation and storage has reached more than 98%, significantly reducing the risk of damage to pharmaceutical packaging.

5. Furniture and household goods packaging

For the packaging of furniture and household goods, Paper Banding Tape can provide reliable fixation and protection. Its soft texture will not scratch the surface of furniture, and it has sufficient strength to fix large furniture parts, such as panels, furniture components, etc. In practical applications, Paper Banding Tape can be used in conjunction with furniture protection pads to further enhance the protective effect. The damage rate of furniture packaging tied with Paper Banding Tape during transportation is reduced by about 30% - 35% compared with traditional bundling methods, effectively reducing customer complaints caused by packaging problems and improving brand image and customer satisfaction.

6. Gift packaging industry

In the field of gift packaging, the aesthetics and customization capabilities of Paper Banding Tape make it an ideal choice. Its good printing adaptability allows exquisite patterns and brand logos to be printed on the strapping tape, adding a unique visual effect to the gift. Compared with traditional ribbons or plastic strapping materials, Paper Banding Tape is more environmentally friendly and meets the expectations of modern consumers for sustainable development. In practical applications, the recycling rate of gift packaging using Paper Banding Tape has increased by about 40% - 50%. At the same time, its high strength and good strapping performance also ensure the integrity of the gift during transportation and handling, enhancing the shopping experience of consumers.

Paper Banding Tape Maintenance:

1. Storage environment control

To ensure the performance and service life of Paper Banding Tape, it should be stored in a dry, ventilated environment, away from moisture and direct sunlight. The ideal storage humidity is 40% - 60% RH and the temperature is 15 - 25℃. In such an environment, the strapping tape can maintain the stability of its physical properties and prevent strength loss and mildew caused by excessive humidity. For example, Paper Banding Tape should be stored on shelves in the warehouse to avoid direct contact with the ground to reduce the impact of ground moisture. Regularly check the temperature and humidity of the storage environment and take appropriate moisture-proof measures, such as placing desiccant, which can effectively extend the shelf life of the strapping tape and ensure that its performance during use is not affected.

2. Avoid contact with sharp objects

When handling and using Paper Banding Tape, try to avoid contact with sharp objects to prevent scratches or punctures of the strapping tape. During storage and transportation, ensure that the strapping tape roll is placed on a stable surface to avoid being squeezed or collided with other objects. If the strapping tape surface is scratched or damaged, its tensile strength and tear resistance will be reduced, affecting the use effect. For example, in the warehouse, the strapping tape coil should be placed on a dedicated shelf and separated by a protective pad to avoid direct contact with other hard objects. During use, the operator should be careful to handle it with care to avoid unnecessary damage to ensure the integrity and reliability of the strapping tape.

3. Reasonable control of tension

When using Paper Banding Tape for bundling, the strapping tension should be reasonably controlled to avoid excessive stretching or insufficient tension. The recommended strapping tension range is 100 - 300 N, and the specific tension should be adjusted according to the characteristics and weight of the bundled items. Excessive stretching may cause the strapping tape to break or lose elasticity, while insufficient tension cannot provide sufficient binding force, causing the items to loosen. For example, when bundling heavier goods, the tension should be appropriately increased, but it should not exceed 70% of the maximum tensile strength of the strapping tape; for lighter items, the tension can be appropriately reduced. By properly controlling the strapping tension, the performance of Paper Banding Tape can be fully utilized to ensure the safety of items during transportation and storage.

4. Regularly check the appearance quality

Before and during use, the appearance quality of Paper Banding Tape should be regularly checked, including whether there are scratches, wrinkles, holes and other defects on the surface. If any problems are found, the strapping tape should be replaced in time to avoid using products with quality problems. For example, before each use, the operator should quickly visually check the surface of the strapping tape coil. If obvious scratches or damage are found, the strapping tape should be stopped immediately and replaced with a new one. Regularly checking the appearance quality can effectively prevent packaging failures caused by strapping tape quality problems, ensure that each batch of strapping operations can achieve the expected results, and improve the overall packaging quality.

5. Correct use of heat sealing equipment

When using heat sealing equipment to seal Paper Banding Tape, ensure that the heat sealing temperature and pressure of the equipment are set correctly. The recommended heat sealing temperature range is 160 - 200℃, the heat sealing pressure is 0.3 - 0.5 MPa, and the heat sealing time is 0.5 - 1.0 seconds. Incorrect heat sealing parameters may result in a loose seal or excessive carbonization, affecting the strength and reliability of the strapping tape. For example, when adjusting the heat sealing equipment, a small batch test should be conducted first to observe the appearance and strength of the seal to ensure that the seal quality meets the requirements. Regular maintenance of the heat sealing equipment, cleaning of the heat sealing components, and inspection of the performance of the heating elements can ensure the stability and consistency of the heat sealing effect and extend the service life of the equipment.

6. Avoid long-term load bearing

Although Paper Banding Tape has high tensile strength and good strapping performance, it should be avoided from being subjected to excessive weight or tension for a long time during use. Long-term load bearing may cause the strapping tape to creep, gradually lose some strength and elasticity, and increase the risk of breakage. For example, in a storage environment, the stacking height and weight of the goods should be reasonably planned to avoid a single strapping tape being subjected to a load exceeding 80% of its rated strength. For items stored for a long time, it is recommended to check the condition of the strapping regularly and, if necessary, readjust the strapping tension or replace the strapping to ensure the safety and stability of the items.

Paper Banding Tape FAQs:

1. Which are the common size options for Paper Banding Tape?

Our Paper Banding Tape comes in the thicknesses of 20mm and 30mm as these are the most commonly used tie widths as far as strapping machines and packaging processes are concerned. Should you require specific paper widths other than the standard, we also offer custom options.

2. What is the composition of Paper Banding Tape?

Our Paper Banding Tapes are crafted from high-quality paper materials that provide excellent tensile strength and reliable performance.

3. Which industries are most likely to make use of the Paper Banding Tape?

The Paper Banding Tape is used in many sectors including packaging, clothing, electronics, and food.