Kraft Paper Strapping Tape

- Product Information

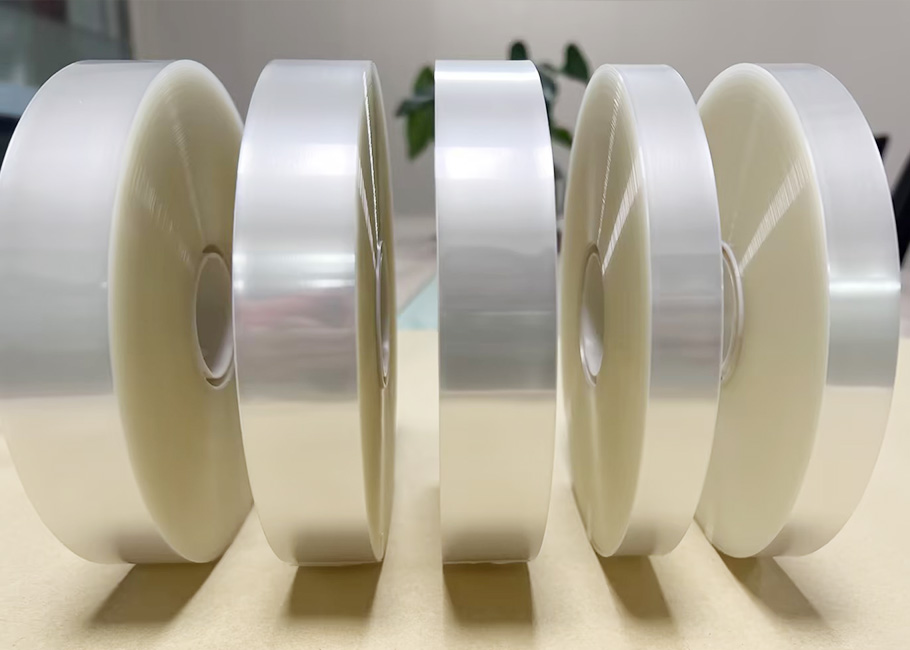

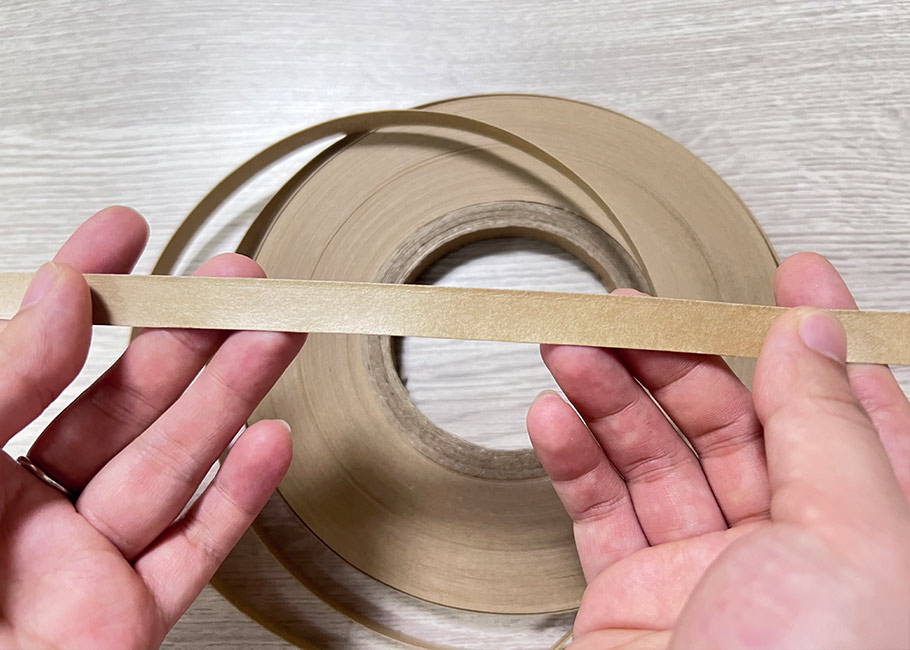

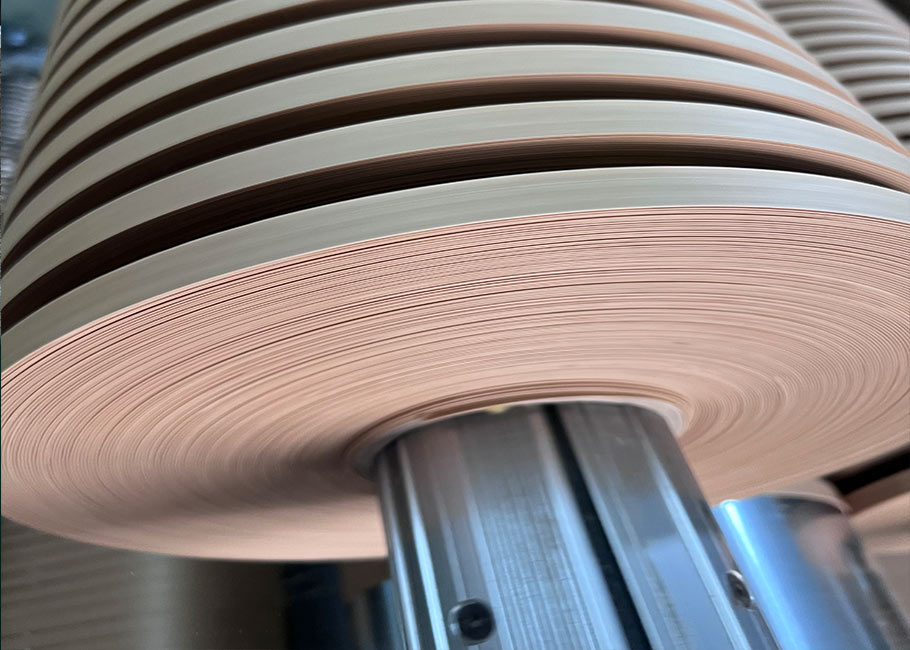

Kraft Paper Strapping Tape is a strapping tape based on Kraft Paper. It is made of multiple layers of kraft paper through a special process, and has good strength and toughness. This tape is usually in roll form with a plastic core inside for easy installation and operation during use. It is an environmentally friendly packaging material that is widely used in packaging and fixing work in various industries.

Kraft Paper Strapping Tape Parameters:

| Material: | Paper |

| Size: | Material Width And Thickness Can Be Customized According To Customer Requirements |

| OEM: | OEM/ODM Available |

| Packaging: | Carton Packaging |

| Factory Nature: | China Manufacturers Suppliers Factory |

Kraft Paper Strapping Tape Features:

Strong: Kraft Paper Strapping Tape has extremely high tensile strength and can withstand large tensile forces without breaking easily. Its tensile strength can reach 2500 N/50mm, which means that when packaging heavy items, it can provide reliable strapping force to ensure that the items will not loosen during transportation and storage. This sturdiness makes it an ideal choice to replace traditional plastic strapping tape, especially when high-strength fixing is required.

Flexible: Despite its high strength, Kraft Paper Strapping Tape also has good flexibility. Its elongation can reach 3%-5%, and it can stretch moderately when stretched by external force without breaking immediately. This flexibility allows the tape to fit better when wrapping irregularly shaped items, reducing looseness caused by irregular shapes. At the same time, flexibility also makes the tape less brittle in low temperature environments, maintaining the stability of its physical properties.

Breathable: Kraft Paper Strapping Tape has unique breathability, with a breathability of 500-800 sec/100cc. This makes it possible to effectively prevent moisture accumulation and mildew caused by a closed environment when packaging items that need to breathe, such as fresh produce or certain moisture-sensitive products. Breathability also helps reduce condensation inside the package, extending the shelf life of the product while avoiding damage to the packaging material caused by moisture.

Environmental protection: From an environmental perspective, Kraft Paper Strapping Tape has significant advantages. It is made of renewable kraft paper, and the raw materials used in the production process come from sustainably managed forest resources. Its degradability is manifested in a decomposition cycle of 60-90 days in the natural environment, which is much faster than the hundreds of years of decomposition time of traditional plastic strapping tape. In addition, the production process of the tape is relatively low-carbon, and the energy consumption per unit product is 30%-40% lower than that of plastic products, which meets the needs of modern enterprises for environmentally friendly packaging materials.

Temperature resistance: Kraft Paper Strapping Tape maintains stable performance over a wide temperature range. Its temperature resistance range is -30℃ to 100℃, and it will not become hard or brittle in low temperature environments, and it can still maintain good flexibility and stickiness. In high temperature environments, such as outdoor storage in summer or storage conditions near heat sources, the tape will not soften or stick, ensuring that the strapping effect is not affected. This temperature resistance makes it suitable for packaging needs in various extreme climate conditions.

Adhesion: Kraft Paper Strapping Tape's adhesion is specially formulated to achieve an initial adhesion of 120-150 g/cm², which can quickly adhere to the surface of a variety of materials. It has strong adhesion and will not loosen after long-term use due to decreased adhesion. The adhesive layer of the tape is tightly bonded to the kraft paper substrate, and the peel strength reaches 15-20 N/25mm, ensuring that no residual adhesive is left when unwrapped, keeping the packaged items clean and intact.

High surface flatness: Kraft Paper Strapping Tape has an extremely high surface flatness, thanks to the precise calendering process during its production process. Its surface roughness can be controlled in the range of 1.5-2.0 μm, allowing the tape to evenly adhere to packaging surfaces of various materials, including smooth plastics, metal paper and materials. High flatness not only improves the aesthetics of the tape, but also increases its contact area with the adherend, thereby improving the overall bonding strength and preventing the edge from lifting or falling off during handling.

Strong impact resistance: In actual use, Kraft Paper Strapping Tape can withstand a certain degree of impact force, mainly due to its multi-layer kraft paper structure and unique lamination process. In the drop hammer impact test, the tape can withstand an impact energy of up to 3.5-4.0 J, which is about 65% higher than that of ordinary paper tape. This impact resistance allows it to maintain the integrity of the bundle even if the goods are slightly bumped or dropped during logistics transportation, reducing the risk of loose packaging.

Good chemical corrosion resistance: Kraft Paper Strapping Tape exhibits good corrosion resistance when facing common chemicals. Its tolerance time to weak acids (such as acetic acid, pH=3-4) and weak bases (such as sodium carbonate solution, pH=9-10) can reach 72-96 hours, and there is no obvious damage to the paper and adhesive layer. This feature means that when packaging some slightly chemically corrosive products (such as detergents, food additives, etc.), the tape can maintain stable performance and will not cause strapping failure or packaging damage due to chemical reactions.

Good printability: The tape has excellent printability, and its surface absorbency is moderate (water absorption rate is between 12%-15%), which can ensure uniform adhesion of ink. When using common printing techniques (such as screen printing, thermal transfer, etc.), the clarity of printed text and patterns can reach more than 95%, and after friction testing, the ink retention rate can still reach 85%-90%. This makes it possible to directly print brand logos, product information or barcodes on the surface of the tape, meeting the company's needs for product recognition and information display.

Kraft Paper Strapping Tape Application:

Logistics packaging: In the logistics industry, Kraft Paper Strapping Tape is one of the preferred materials for bag strapping. It can firmly bind multiple cartons together to form a stable transport unit, improving the stability of goods during transportation. Compared with traditional plastic strapping tape, its flexibility makes it less likely to break due to collision during loading and unloading, while its breathability reduces the problem of packaging expansion caused by the breathing of goods. In addition, the environmental protection characteristics of the tape meet the requirements of modern logistics companies for green supply chains, especially in cross-border transportation, and can meet the environmental protection regulations of different countries.

Food industry: Food packaging has extremely high safety requirements, and Kraft Paper Strapping Tape is widely used in this field. It is often used to bundle food pallets or cartons to ensure that food is not contaminated during transportation and storage. Due to its breathability, it can effectively extend the shelf life of some fresh products that need to breathe, such as fruits and vegetables. At the same time, the environmentally friendly material and non-toxic and odorless characteristics of the tape meet the hygiene standards of food packaging, will not have any harmful effects on food, and ensure food safety.

Electronic products: In the packaging of electronic products, Kraft Paper Strapping Tape can provide a reliable fixing solution. Its good insulation performance prevents static electricity from damaging electronic components, and its flexibility allows for better fit and reduced shaking when packaging irregularly shaped electronic products. Due to its environmentally friendly characteristics, it meets the green requirements of the electronics industry for packaging materials, especially in export products, it can meet international environmental standards and avoid the risk of returns due to non-compliance of packaging materials.

Construction industry: In the construction industry, Kraft Paper Strapping Tape is used to bundle building materials such as tiles and panels. Its high strength can withstand the weight of building materials and ensure safety during handling and storage. Breathability helps reduce packaging damage caused by moisture in building materials, and its environmentally friendly characteristics meet the construction industry's requirements for the promotion of environmentally friendly materials. In addition, the tape's temperature resistance enables it to maintain a good bundling effect under various climatic conditions on construction sites, regardless of seasonal changes.

Pharmaceutical field: Pharmaceutical product packaging has strict requirements on sealing and safety, and Kraft Paper Strapping Tape plays an important role in this field. It is used to bundle pharmaceutical cartons or pallets to ensure that the drugs are not contaminated during transportation. The breathability of the tape helps prevent the drug from deteriorating due to moisture accumulation inside the drug packaging, while its environmental and non-toxic properties meet the strict hygiene standards of the pharmaceutical industry. In addition, the adhesive design of the tape ensures that the drug packaging will not be damaged when unwrapped, maintaining the integrity of the packaging.

Agricultural Applications: In the agricultural field, Kraft Paper Strapping Tape is used to bundle agricultural products, such as bagged grains, feed, etc. Its high strength can withstand the weight of agricultural products and ensure stability during handling and storage. Breathability is essential for the respiration of agricultural products, which can effectively reduce mold and deterioration problems caused by closed environments. The environmental characteristics meet the agricultural industry's requirements for sustainable development, and the durability of the tape enables it to maintain good performance in outdoor environments without being affected by sunlight and humidity.

Kraft Paper Strapping Tape Maintenance Tips:

Storage Environment

The storage environment of Kraft Paper Strapping Tape needs to be strictly controlled to ensure that its performance is not affected. The tape should be stored in a dry, ventilated indoor environment with a temperature controlled at 15℃-30℃ and a relative humidity maintained at 40%-60%. Avoid exposing the tape to high temperature, high humidity or direct sunlight, as these factors will cause the physical properties of the tape to deteriorate, such as weakened viscosity and brittle paper. It is recommended to store the tape on a shelf at least 10 cm from the ground to avoid contact with ground moisture. At the same time, the storage area should be away from heat sources and chemically corrosive substances to ensure that the tape remains in optimal condition during storage.

Avoid light

Light is one of the important factors that affect the performance of Kraft Paper Strapping Tape. Long-term exposure to sunlight or strong light will cause the ultraviolet rays to gradually age the paper of the tape, turn yellow in color, and reduce its strength. Studies have shown that for every 100 μW/cm² increase in ultraviolet radiation intensity, the tensile strength of the tape decreases by about 5%-8% per month. Therefore, the tape should be stored in a light-proof environment, such as using blackout curtains or storing in opaque packaging boxes. During use, minimize the exposure time of the tape to outdoor sunlight. If temporary storage is required, it is recommended to cover the tape with protective materials to block ultraviolet rays to extend the service life of the tape.

Moisture and humidity prevention

Kraft Paper Strapping Tape is sensitive to humidity, so moisture and humidity prevention are key aspects of maintenance. When the ambient humidity exceeds 60%, the paper absorbs moisture from the air, causing the strength of the tape to decrease and the viscosity to weaken. Experiments show that for every 10% increase in humidity, the tensile strength of the tape decreases by about 15%-20%. To prevent moisture, the tape should be stored in the original packaging in a sealed manner and avoid long-term exposure to the air after opening the packaging. In a humid environment, dehumidification equipment can be used to reduce humidity, or desiccant such as silica gel desiccant can be placed in the storage area, 500-1000 grams per cubic meter of space, and replaced regularly to maintain a dry environment. In addition, check whether the tape has signs of moisture before use, and if so, it should be handled or replaced in time.

Regular Inspection

Regular inspection of Kraft Paper Strapping Tape is an important measure to ensure its performance. The recommended inspection frequency is once a month, and the main inspection contents include the appearance, viscosity and strength of the tape. Observe whether the surface of the tape is discolored, wrinkled or damaged. If yellow spots or obvious deformation are found on the paper surface, it indicates that the tape may be damp or aged. Check the strength of the tape through a tensile test. If it feels easier to break than a new tape, it means that the strength has decreased. At the same time, to test the viscosity, you can stick the tape on a standard test board and measure the adhesion after 24 hours. If the viscosity decreases by more than 30%, you need to consider replacing the tape. Record the results of each inspection so that performance trends can be discovered in time.

Usage Specifications

When using Kraft Paper Strapping Tape, you need to follow the correct operating specifications to extend its service life. First, make sure to use the appropriate tools for installation, such as a dedicated tape slitter or strapping machine, to avoid excessive stretching during use that may damage the paper fibers. When bundling items, the tension should be moderate so that the tape can adhere to the surface of the item but not be significantly deformed. Studies have shown that overstretching the tape by more than 8% of its original length can significantly reduce its tensile strength and increase the risk of breakage by 40%-50%. When untying the tape, special tools should be used to avoid tearing it hard by hand to avoid damaging the edge of the paper and affecting the next use. For used tapes, if there are stains on the surface, you can gently wipe it with a damp cloth, but make sure the tape is dry before storing it.

Cleaning and Maintenance

Kraft Paper Strapping Tape cleaning and maintenance are critical to maintaining its performance. During storage and use, the surface of the tape may be contaminated with dust, oil or other impurities, which will affect the stickiness and appearance of the tape. When cleaning, use a soft damp cloth to gently wipe the surface of the tape, and avoid using rough materials to avoid scratching the paper. For stubborn stains, use a neutral detergent diluted at a ratio of 1:10 and wipe it, then wipe it with a damp cloth and dry it thoroughly. Note that the pH value of the detergent should be between 6-7.5. Detergents with too strong acidity and alkalinity will corrode paper fibers and cause strength loss. During the cleaning process, avoid soaking the tape in water to prevent the paper from absorbing water and swelling, which will affect the performance. The cleaned tape should be placed in a ventilated place to dry, and it should be completely dry before storage or use.