Heat Seal Banding Tape

- Product Information

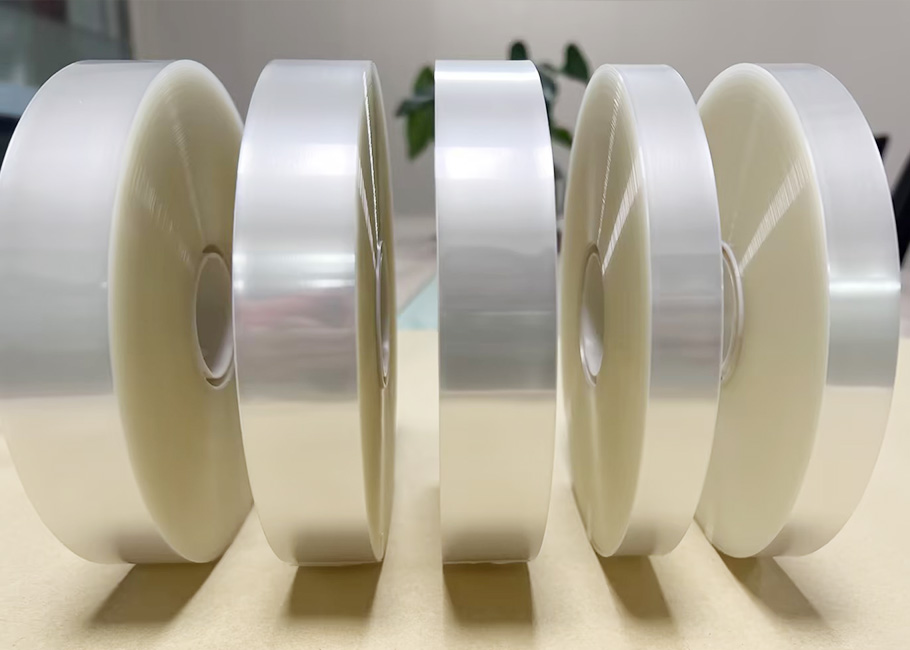

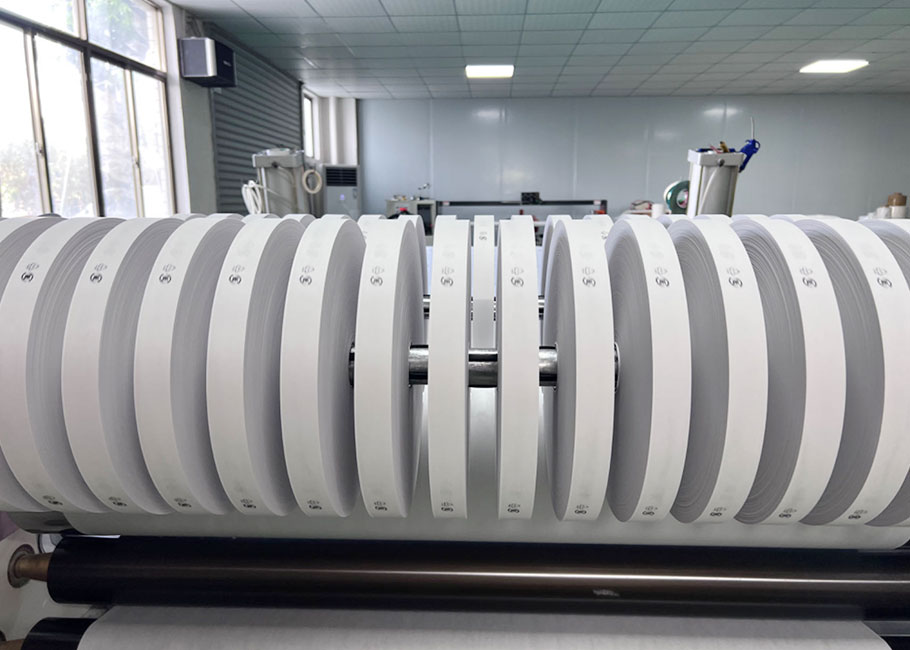

Heat Seal Banding Tape is a type of strapping product made of paper as the main material. From the appearance, it is usually in roll form, mostly pure white in color, and of course it can be dyed or otherwise surface treated as needed. This tape has unique heat-sealing properties. Under heating conditions, its hot melt layer will melt, thereby tightly bonding with the bundled object or other tape layers to achieve the bundling and binding of the product. It has commonly used 20MM and 30MM width specifications, and can also customize the width and thickness of the material according to the specific requirements of the customer. It is widely used in packaging, clothing, electronics and other industries, and is an indispensable auxiliary material in modern industrial production and logistics transportation.

Heat Seal Banding Tape Parameters:

| Material: | Paper |

| Size: | Customizable Width And Thickness According To Customer Requirements |

| OEM: | OEM/ODM Available |

| Packaging: | Carton |

| Factory Nature: | China Manufacturers Suppliers Factory |

Heat Seal Banding Tape Features:

Good tensile strength: Heat Seal Banding Tape has excellent tensile performance. After rigorous professional tensile testing, its tensile strength can reach more than 55N/cm at room temperature. This excellent tensile property enables it to withstand heavy weight pulling without breaking easily when bundling products. For example, when bundling heavy industrial parts, even if the parts are subjected to large tensile forces caused by bumps and shaking during transportation, the tape can still maintain a stable bundling state, effectively preventing the product from scattering and ensuring the safety of the product during transportation and storage.

Good heat sealing effect: Heat sealing performance is one of the core advantages of this tape. Under specific heat sealing conditions, the heat sealing strength can be as high as 35N/15mm or more. When the tape is heated, its hot melt layer can melt quickly and evenly, tightly bonded to the bonded material, and form a firm seal. This good heat sealing effect not only ensures that the bundled products will not easily loosen in various environments, but also improves the sealing of the packaging. For example, when packaging and bundling food, it can effectively prevent air, moisture, etc. from entering the packaging, extend the shelf life of food, and maintain the freshness and taste of food.

Environmentally friendly materials: paper material is used, which has significant environmentally friendly and degradable characteristics. Compared with traditional plastic strapping materials, it will not remain in the environment for a long time and cause pollution. In the natural environment, after a period of time, paper tape can gradually decompose into harmless substances, which meets the high requirements of modern society for environmentally friendly materials. For those companies committed to green production, the use of this environmentally friendly tape can help enhance the social image of the company, meet consumers' demand for environmentally friendly products, and also meet the requirements of relevant environmental regulations.

Flexible customization: The width and thickness of the material can be customized according to customer requirements. The width customization range can be between 10-120mm, and the thickness customization range can be between 0.1-0.6mm. This high degree of flexibility enables the tape to meet the diverse strapping needs of different industries and different products. For example, in the electronics industry, for the fine bundling of small electronic components, narrower and thinner tapes can be customized to ensure the accuracy of bundling and not affect the normal use of components; in the construction industry, for the bundling of large building materials, wider and thicker tapes can be customized to provide sufficient tension and stability.

Strong printing adaptability: The tape has good printing adaptability and can print various patterns and texts on its surface. The printed patterns are clear, colorful, and not easy to fade. Enterprises can make full use of this feature to print brand logos, product information, promotional slogans and other content on the tape. This not only enhances the brand image and product recognition, but also facilitates product management and identification. For example, in the logistics industry, logistics order numbers, sending and receiving information, etc. can be printed on the tape to facilitate the tracking and management of goods.

Good weather resistance: Under different climatic conditions, the tape can maintain good performance stability. After testing to simulate a variety of extreme environments, its tension and heat sealing performance changes very little in an environment with a temperature of - 25℃ to 70℃ and a relative humidity of 15% to 95%. This means that whether in the cold northern winter or the hot southern summer, whether in the dry desert area or the humid coastal area, the tape can play the role of bundling and heat sealing normally, ensuring the reliability of product packaging.

Easy to operate: The operation of the heat-sealed strapping tape is very simple, and no complex equipment and professional skills are required. The staff only needs to wrap the tape around the product and then heat and seal it through the heat-sealing equipment. Compared with some strapping materials that require professional training to operate, it greatly improves work efficiency and reduces labor costs. For example, in the express delivery industry, couriers can quickly use the tape to bundle and seal the package, speeding up the processing of the package.

High cost-effectiveness: Compared with other similar strapping materials, the tape has a higher cost-effectiveness. Its price is relatively reasonable, and at the same time, due to its stable performance and durability, it reduces the cost caused by frequent replacement of strapping materials. In the long-term use process, it can save a lot of packaging costs for the enterprise. Taking a medium-sized manufacturing enterprise as an example, after using the heat-sealed strapping tape, the annual cost of packaging materials can be reduced by 20% - 30%, which improves the economic benefits of the enterprise.

Heat Seal Banding Tape Application:

Packaging industry: Heat Seal Banding Tape plays a vital role in the packaging of various products. Whether it is food, daily necessities, cosmetics or industrial products, it can be seen. In food packaging, it can be used to seal snack bags, packaging boxes, etc. to prevent food from getting damp and deteriorating; in daily necessities packaging, it can be used to bundle bottled products such as shampoo and shower gel to prevent bottles from tipping over or breaking during transportation; for industrial products such as machinery and equipment, spare parts, etc., the tape can be firmly bundled for easy transportation and storage.

Clothing industry: Clothing needs to be bundled and packaged during production and sales. Heat seal strapping tape can be used for bundled packaging of clothing, making the clothing neat and orderly for easy storage and transportation. The tape can also be used for the label pasting of clothing to ensure that the label is firmly attached to the clothing. In addition, its customizable characteristics can customize tapes of different widths, colors and printing patterns according to the styles and needs of different clothing brands to enhance the brand image. For example, high-end fashion brands can customize tapes with brand logos and unique design elements to increase the added value of products.

Electronics industry: Electronic products are usually more delicate and require reliable strapping materials to ensure their safety during transportation and storage. Heat-sealed strapping tape has good tensile strength and good heat-sealing effect, which can meet the strapping needs of electronic products. For example, mobile phones, computer accessories, etc. are strapped to prevent them from shaking in the packaging box and avoid damage due to collision. At the same time, its environmental protection characteristics also meet the requirements of the electronics industry for environmentally friendly materials, and the customizable specifications can adapt to electronic products of different sizes and shapes.

Logistics industry: In logistics transportation, a large number of goods need to be strapped and fixed. Heat-sealed strapping tape can be used for packaging and strapping of goods to ensure that the goods are stable and immobile in the transport vehicle or container, reducing the risk of damage to the goods. Its easy operation also improves the efficiency of logistics packaging and speeds up the turnover of goods. For example, in the express sorting center, staff can quickly use the tape to strap packages, improve the processing efficiency of express delivery, and ensure that the goods can be delivered in time.

Stationery industry: Stationery products also need to be strapped and packaged during production and sales. Heat-sealed strapping tape can be used for bundled packaging of stationery such as notebooks, folders, pens, etc., making the stationery neat and beautiful, and convenient for display and sales. At the same time, the logo and slogan of the stationery brand can be printed on the tape to enhance brand awareness. When schools and offices purchase stationery, neatly bundled stationery is also convenient for management and distribution.

Crafts industry: Crafts usually have unique shapes and high value, and need to be carefully packaged and bundled. Heat-sealed strapping tape can be used for the packaging and bundling of crafts, which can not only ensure the safety of crafts during transportation and storage, but also increase the artistic sense and gift sense of crafts through customized printed patterns. For example, handmade ceramics, wood carvings, embroidery and other crafts are bundled and packaged to improve the overall quality of the product and make it more suitable for gift giving.

Pharmaceutical industry: Pharmaceutical products have extremely high requirements for the sealing and safety of packaging. The good heat sealing effect of heat-sealed strapping tape can ensure the sealing of pharmaceutical products and prevent drugs from getting damp and deteriorating. In the box packaging or carton packaging of medicines, the tape is used for bundling to ensure the stability of the medicines during transportation and storage, which meets the strict standards of the pharmaceutical industry. At the same time, its environmentally friendly material also ensures the safety of the medicines and will not pollute the medicines.

Toy industry: Toys need to be bundled and packaged during production and sales to prevent the toys from scattering during transportation and display. The heat-sealed bundling tape has good tensile strength and can be customized, so that it can meet the bundling needs of different types of toys. At the same time, its environmentally friendly material also meets the toy industry's requirements for safety and environmental protection, and protects children's health. For example, bundling plush toys, plastic toys, etc. makes the toys more neatly displayed on the shelves and attracts consumers' attention.

Hardware industry: Hardware tools and parts are usually irregular in shape and heavy in weight, requiring reliable bundling materials. Heat-sealed bundling tape can be used for bundling hardware products, such as screws, nuts, wrenches, etc., to ensure that hardware products will not scatter during transportation and storage, which is convenient for management and sales. In the warehouse of the hardware factory, the tape is used to classify and bundle the hardware products, which is convenient for workers to take and inventory.

Agricultural product industry: In the packaging and transportation of agricultural products, heat-sealed strapping tape is also widely used. For example, the packaging boxes of vegetables and fruits are bundled to prevent the packaging boxes from opening during transportation and protect the agricultural products from damage. At the same time, its environmental protection characteristics also meet the requirements of the agricultural product industry for green packaging. In agricultural product wholesale markets and supermarkets, agricultural products bundled with this tape are more neatly packaged, which is convenient for consumers to select and buy.

Heat Seal Banding Tape Maintenance:

Storage environment: Heat-sealed strapping tape should be stored in a dry, ventilated, and cool environment, avoiding direct sunlight and high temperature and humidity. Direct sunlight will cause the surface color of the tape to fade and the material to age, while high temperature and high humidity will easily cause the tape to become damp and moldy, affecting its viscosity and tensile properties. The ideal storage temperature is 15-25℃ and the relative humidity is 40%-60%. In such an environment, the tape can maintain good physical and chemical properties and extend its service life. Temperature and humidity monitoring equipment can be installed to monitor the temperature and humidity changes in the storage environment in real time.

Avoid heavy pressure: During storage and transportation, avoid heavy pressure on the tape. Heavy pressure may cause deformation and damage to the tape, affecting its use effect. If stacking is required, the height and weight of the stack should be controlled to ensure that the bottom tape is not subjected to excessive pressure. At the same time, it should be handled with care to avoid collisions and falls. Special shelves can be used to store tape to ensure that the tape is placed stably.

Regular inspection: Regularly check the storage status of the tape to observe whether it is damp, moldy, damaged, etc. If a problem is found, timely measures should be taken to deal with it. For example, for damp tape, it can be placed in a well-ventilated place for drying, but be careful to avoid exposure to sunlight to prevent the tape from becoming brittle; for damaged tape, it should be marked and isolated in time to prevent misuse. A regular inspection plan can be formulated, such as monthly inspection.

Prevent pollution: During use and storage, the tape should be prevented from being contaminated by oil, dust, etc. Oil will affect the heat sealing performance of the tape, and dust may affect the appearance and printing effect of the tape. When using, the operating environment should be kept clean, and the operator can wear gloves to avoid direct contact between the oil on the hands and the tape; when storing, the tape can be packaged with plastic film or cartons to prevent the intrusion of dust and pollutants.

Reasonable use: When using the tape, it should be used reasonably according to the needs of the product and the specifications of the tape. Avoid over-stretching or abusing the tape to avoid affecting its tensile force and heat sealing performance. At the same time, it is necessary to select the appropriate heat sealing temperature and time to ensure the best heat sealing effect. Different heat sealing equipment may require different parameter settings, and operators should operate according to the equipment manual. For example, if the heat sealing temperature is too high, the tape may melt excessively and affect the sealing strength; if the temperature is too low, a good heat sealing effect may not be achieved.

Avoid contact with chemicals: Avoid contact between the tape and strong acids, strong alkalis and other chemicals to avoid chemical reactions and affect its performance. If you accidentally come into contact with chemicals, you should immediately rinse with plenty of water and take appropriate treatment measures according to the properties of the chemicals. For example, if you come into contact with strong acids, you can use alkaline solutions for neutralization, but pay attention to operating safety to avoid splashing the solution on your skin.

Transportation protection: When transporting the tape, take protective measures to prevent damage during transportation. You can use packaging materials such as cartons and wooden boxes for packaging, and fill the packaging with cushioning materials such as foam plastics and bubble films to prevent the tape from shaking and colliding during transportation. For long-distance transportation, you should choose appropriate transportation tools and transportation routes to avoid bumps and vibrations. At the same time, during transportation, the packaging should be checked regularly to see if it is intact. If there is any damage, it should be repaired in time.

Record management: Establish an inventory management system for tapes to record information such as the time of entry, quantity, specifications, and usage. Through record management, you can timely understand the inventory status of tapes, arrange procurement and use reasonably, and avoid inventory backlogs or shortages. At the same time, it also helps to trace and analyze when problems arise. You can use electronic management systems or paper archives to record to ensure the accuracy and completeness of the records.

Heat Seal Banding Tape FAQs:

1. Which are the common size options for Heat Seal Banding Tape?

Our Heat Seal Banding Tape comes in the thicknesses of 20mm and 30mm as these are the most commonly used tie widths as far as strapping machines and packaging processes are concerned. Should you require specific paper widths other than the standard, we also offer custom options.

2. What is the composition of Heat Seal Banding Tape?

Our Heat Seal Banding Tapes are crafted from high-quality paper materials that provide excellent tensile strength and reliable performance.

3. Which industries are most likely to make use of the Packaging Paper Ties?

The Heat Seal Banding Tape is used in many sectors including packaging, clothing, electronics, and food.