xinyuanshun@xyspaper.com

|

+86-13316621858

+86-0750-3766098

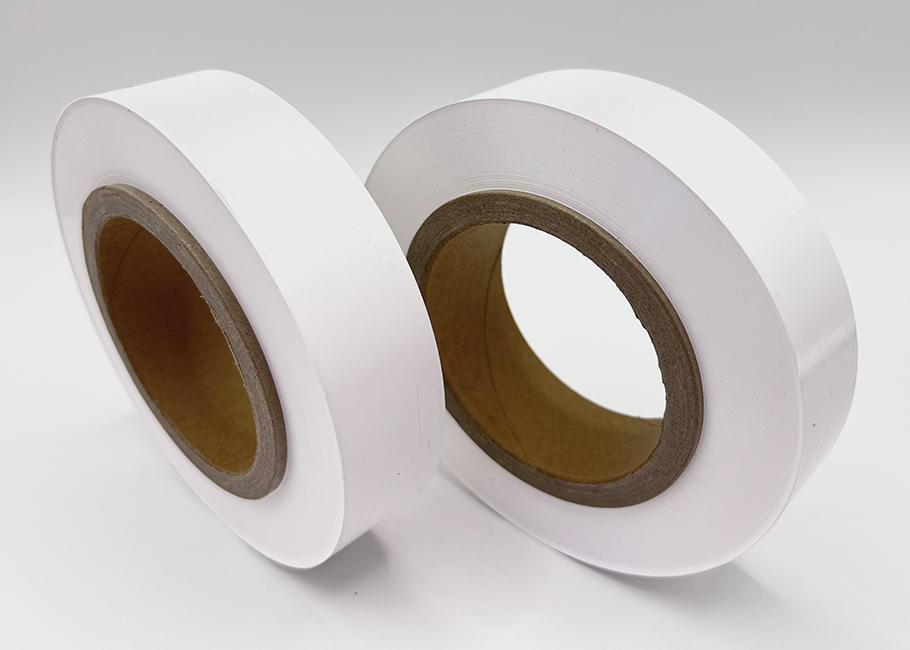

The lithium ion separator is a key functional material located between the positive and negative electrodes of a battery. It is primarily composed of polypropylene and polyethylene. It physically separates the positive and negative electrodes within the battery, preventing direct contact and short circuits while allowing lithium ions to flow freely during charging and discharging. High-quality separators significantly improve battery safety and cycle life, allowing users to experience more stable performance and reduced risk of thermal runaway when using electronic products or electric vehicles.

High-quality polymer materials

The lithium ion separator utilizes a multi-layer co-extruded polypropylene and polyethylene composite material. The PP layer provides rigid support, while the PE layer contributes to closed-cell properties. The material purity exceeds 99.9% and the ash content is less than 50 ppm, ensuring electrochemical stability. The PP/PE ratio can be adjusted to suit the battery system to optimize thermal shutdown performance and mechanical strength.

Excellent electronic insulation

With a volume resistivity exceeding 1×10¹⁵ Ω·cm and a surface resistivity exceeding 1×10¹⁴ Ω/□, it effectively prevents electron migration between the positive and negative electrodes. With a dielectric strength of 300V/μm, it maintains stable isolation performance in high-voltage battery systems and prevents internal short circuits.

Precise Pore Size Control

The pore size distribution ranges from 0.03-0.12μm, with an average pore size of 0.045μm and a controlled porosity between 35% and 45%. Using a dry uniaxial stretching process, the pores are elliptical in shape, ensuring a lithium ion transference number exceeding 0.35, reducing battery internal resistance.

High Puncture Strength

A puncture strength exceeding 450gf/μm effectively prevents electrode active material particles from piercing the separator. The multi-layer composite structure ensures that even if a single layer is punctured, the remaining layers remain intact, significantly improving battery safety.

Excellent Tensile Strength

The longitudinal tensile strength exceeds 120MPa, the transverse tensile strength is no less than 100MPa, and the elongation at break is controlled between 90% and 150%. This high strength ensures that the separator does not tear during battery winding, maintaining structural integrity. Excellent thermal stability. The melting temperature is 135°C-145°C, and the thermal shrinkage is less than 5% in both the longitudinal and transverse directions at 160°C. The closed-cell temperature is 130°C ± 2°C, and the open-cell temperature is 150°C ± 3°C. The highly accurate temperature response ensures timely interruption of thermal runaway reactions.

Power Battery Systems

Lithium ion separators are used in electric vehicle power battery packs. The separator thickness is typically 16-20μm, requiring a puncture strength exceeding 500gf/μm. The thermal shrinkage is less than 3% at 60°C, ensuring safe operation of the battery pack under harsh operating conditions and a cycle life of over 2,000 cycles.

Consumer Electronics Batteries

Used in smartphone and tablet batteries, the separators have a thickness of 12-16μm and a porosity of 40% ± 2%. They must meet 3C certification requirements, maintain chemical stability at a high voltage of 4.35V, and support fast charging and discharge rates up to 5C.

Energy Storage Battery Systems

Used in grid-level energy storage batteries, the separators have a thickness of 20-25μm and require a uniform pore size distribution. Maintain ionic conductivity within the temperature range of -40°C to 85°C, with a cycle life of at least 8,000 cycles and a calendar life exceeding 15 years.

Power Tool Batteries

For use in high-rate discharge power tools, the diaphragm must have low internal resistance. It supports continuous discharge exceeding 10C and a thermal shutdown response time of less than 30 seconds, ensuring safety during high-power output.

Aerospace Power Supplies

For use in aircraft backup power systems, meeting DO-160G standards. The diaphragm must maintain structural stability in low-pressure environments, meet radiation resistance standards, and operate within a temperature range of -55°C to 125°C.

Storage Environment Control

The diaphragm should be stored in a clean environment at 20°C ± 5°C and a humidity of ≤30% RH. It is recommended to use aluminum foil packaging and nitrogen filling to prevent oxidation and deterioration. The storage period should not exceed 12 months; performance indicators must be retested after this period.

Production Process Protection

During the battery assembly process, the cleanliness level must meet Class 10,000 or higher. The unwinding tension of the diaphragm should be controlled between 2-5 N/m² to avoid excessive stretching that could cause pore deformation. The winding speed should not exceed 20 m/min to prevent static electricity accumulation.

Quality Inspection Standards

Each batch of diaphragm must be sampled and tested for pore size distribution, porosity, and puncture strength. Pore size is measured using ASTM D6287, and air permeability is tested using ISO 4591, ensuring that key performance indicators remain within ±5%.

Equipment Maintenance Requirements

The blade gap of the diaphragm slitting equipment must be calibrated daily to maintain cutting edge sharpness. The surface roughness of the guide roller must be Ra ≤ 0.2 μm to prevent scratching of the diaphragm surface. The static eliminator must be maintained in working order, and the ionizing air bar must be kept 100-150 mm away from the membrane surface.

Transportation Precautions

During transportation, moisture-proof packaging must be used to avoid direct sunlight. Throwing during loading and unloading is strictly prohibited, and stacking height should not exceed 5 layers. The transportation temperature must be controlled between 15-30°C to prevent high temperatures from causing diaphragm deformation.

Previous: How Thick Is Kraft Paper?