xinyuanshun@xyspaper.com

|

+86-13316621858

+86-0750-3766098

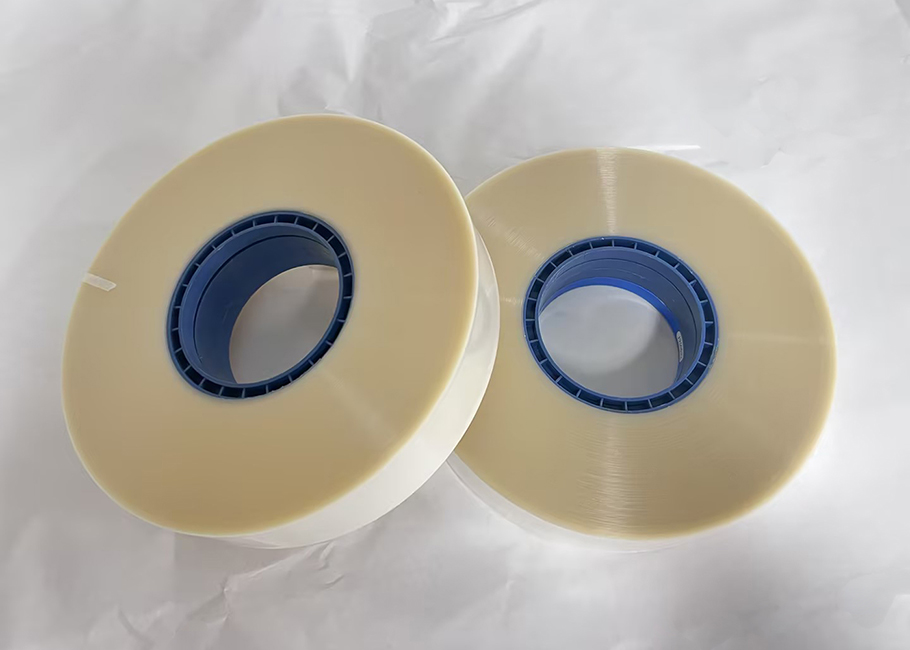

hot melt strapping is a type of hot melt tape used for packaging and bundling. It leverages the stickiness and strength of hot melt adhesive to secure products together. Typically made from PET (polyethylene terephthalate), this tape offers excellent tensile strength and heat-sealing properties, rapidly curing at high temperatures to form a strong bond. Its efficient bundling and packaging capabilities ensure product integrity and safety during transportation and storage.

High-Quality PET Material

Hot Melt Strapping is made from high-quality PET material, which offers high tensile strength and excellent toughness. According to test data, the PET material has a tensile strength of 50-80 MPa and an elongation of 50%-150%, ensuring that the tape is resistant to breakage or deformation during use.

Excellent Heat Sealing Performance

This tape exhibits excellent heat sealing properties, rapidly curing at high temperatures to form a strong bond. The heat sealing temperature range is typically between 120-180°C, ensuring fast sealing in common industrial heat sealing equipment. According to experimental data, the heat-sealed tape achieves a bond strength of 15-20 N/cm, effectively preventing the bundle from loosening or falling apart, ensuring product stability during transportation and storage.

High Tensile Strength

Hot Melt Strapping has high tensile strength, capable of withstanding significant tensile forces without breaking. Tests have shown that it can withstand a longitudinal tensile force of up to 1000 N/cm and a transverse tensile force of up to 800 N/cm. This ensures it maintains its shape during use and resists tearing due to external forces.

Excellent Packaging Results

This tape has a uniform thickness, typically between 0.1 and 0.3 mm, providing excellent cushioning and protection for products. Its smooth surface is dust-free and fiber-free, preventing scratches or contamination.

Fast Curing

Hot Melt Strapping offers fast curing, quickly forming a strong bond after heat sealing. According to experimental data, the tape cures in just 1-3 seconds after heat sealing, significantly improving packaging and strapping efficiency.

Packaging Industry

Hot Melt Strapping is a commonly used strapping material in the packaging industry, widely used for bundling cartons, plastic film, and other packaging materials. Its high tensile strength and excellent heat-sealing properties ensure the integrity of packages during transportation and storage, preventing them from loosening or becoming damaged. Based on actual application data in the packaging industry, the use of this tape has increased the integrity rate of packages during long-distance transportation by approximately 25% and packaging efficiency by approximately 30%.

Warehousing and Logistics

In warehousing and logistics, Hot Melt Strapping is used to secure and strap pallets, ensuring their stability during handling and storage. Its rapid curing properties and high tensile strength effectively prevent cargo from shifting or collapsing, improving warehouse safety and efficiency. Logistics companies have reported that the use of this tape has reduced cargo loss by approximately 20% and increased warehouse space utilization by approximately 15%.

Electronic Product Packaging

In electronic product packaging, Hot Melt Strapping is used to protect sensitive electronic components and devices. Its dust-free and fiber-free surface ensures the cleanliness of electronic products and prevents short circuits or performance degradation caused by impurities. At the same time, its excellent isolation performance prevents electronic products from being squeezed and scratched during transportation.

Storage Environment Control

Hot Melt Strapping should be stored in a dry, well-ventilated environment, away from moisture and direct sunlight. The ideal storage humidity is 40%-60% and the temperature is 15-25°C. Moisture will soften the tape and reduce its adhesion, affecting its strapping performance.

Avoid Mechanical Damage

During handling and use, hot melt strapping should be protected from scratches by sharp objects or pressure from heavy objects. Although the tape has high strength and toughness, excessive mechanical stress can still cause it to crack or deform, affecting its performance.

Prevent Chemical Contamination

Hot melt strapping should be protected from strong acids, strong bases, or other highly corrosive chemicals. Although the tape has a certain degree of chemical resistance, prolonged contact with highly corrosive substances can still degrade or damage it.

Regular Quality Inspection

Regularly inspect the quality of hot melt strapping to ensure that its heat sealing and physical properties meet the requirements. Inspections should include the tape's appearance, thickness, tensile strength, and bond strength. If the tape surface is found to be scratched, damaged or discolored, it should be replaced in time.