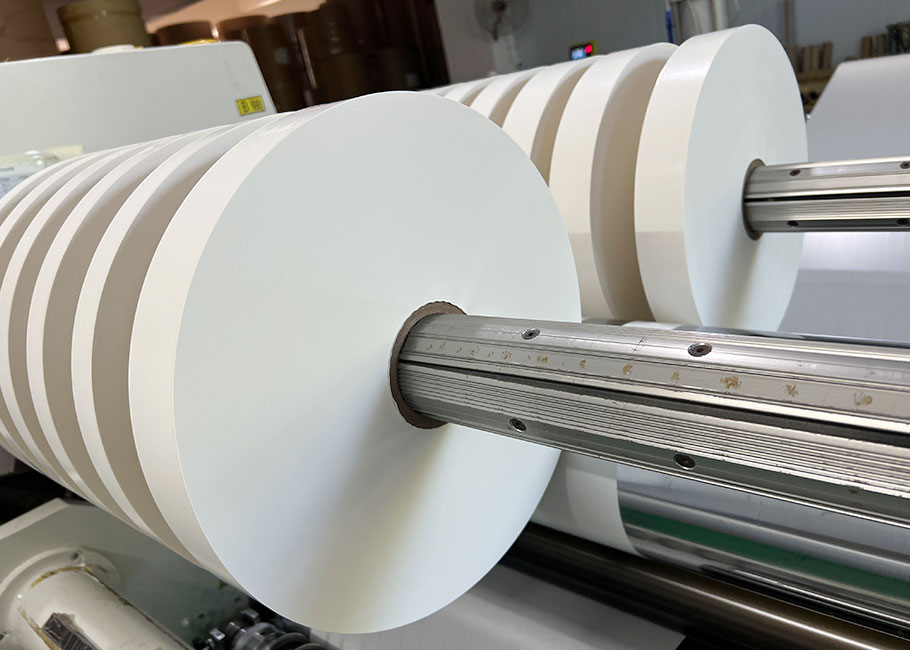

White Medical Packaging Paper

- Product Information

medical packaging paper is a Kraft Paper material specifically designed for the medical and pharmaceutical industries. Made from high-quality kraft paper, it undergoes a specialized aseptic treatment process to ensure sterility and non-toxicity, effectively protecting medical supplies and pharmaceuticals from contamination. This Packaging Paper offers exceptional durability and customizability, with widths and thicknesses customizable to meet customer needs, providing a reliable solution for packaging medical supplies and pharmaceuticals.

Medical Packaging Paper Parameters:

| Material: | Kraft Paper |

| Size: | Customizable Width And Thickness According To Customer Requirements |

| OEM: | OEM/ODM Available |

| Packaging: | Carton |

Medical Packaging Paper Features:

1. High-Quality Kraft Paper

Medical Packaging Paper is made from high-quality kraft paper, which boasts high fiber strength and excellent toughness, providing a foundation for excellent physical properties. Kraft paper is primarily composed of wood fibers, and after special processing, its tensile strength reaches 25-30N/15mm, significantly exceeding the 10-15N/15mm of ordinary paper.

2. Strict Sterility

This packaging paper undergoes a rigorous aseptic processing process, utilizing a combination of high-temperature and high-pressure sterilization and ethylene oxide sterilization to ensure product sterility. Verified by a third-party testing agency, its sterility assurance level reaches 10⁻⁶, meaning the probability of contamination is only 1 in 10⁶ per million units.

3. Non-Toxic Properties

Medical Packaging Paper complies with multiple international food safety and medical standards. Its formaldehyde emissions are below 0.03mg/kg, and heavy metal contents (such as lead, mercury, and cadmium) are below detection limits. These stringent quality controls ensure that the packaging paper releases no harmful substances during use, harming human health and the environment.

4. Durability

This packaging paper exhibits excellent durability, maintaining its performance in a variety of harsh environments. Its burst strength reaches 1200-1500 kPa, and its folding endurance reaches 1000-1200 times, significantly exceeding the 500-800 times of ordinary packaging paper. This durability effectively resists external physical damage during transportation, storage, and use, protecting the contents from damage.

5. High Customizability

Medical Packaging Paper can be customized in width and thickness to meet customer needs. The customization range is extensive, with thickness adjustable from 0.1-0.3 mm and width from 10-100 cm. Users can customize the product to their specific needs.

6. Environmental Performance

This wrapping paper utilizes an environmentally friendly production process, eliminating the use of harmful chemicals. Its wastewater treatment rate exceeds 98%, and its exhaust emissions meet environmental standards. It is naturally biodegradable after use, minimizing environmental pollution. Furthermore, its production primarily utilizes renewable energy, resulting in 30%-40% lower carbon emissions than traditional packaging materials, aligning with modern environmental protection concepts.

Medical Packaging Paper Applications:

1. Medical Device Packaging

In the medical device packaging sector, Medical Packaging Paper is widely used for packaging disposable medical devices (such as syringes, infusion sets, and scalpels). Its sterile and non-toxic properties ensure that medical devices remain sterile after packaging, preventing microbial contamination and extending the shelf life of the products. Medical device manufacturers have seen their product sterility pass rate increase from 95% to 99.9% after using Medical Packaging Paper, significantly improving product quality and safety and providing a reliable packaging solution for the medical industry.

2. Pharmaceutical Packaging

In the pharmaceutical industry, this packaging paper is used for packaging pharmaceuticals such as tablets, capsules, and powders. Its excellent breathability and water-repellent properties keep the drugs dry while preventing damage from moisture and water. Furthermore, its sterile and non-toxic properties ensure that the drugs are not contaminated after packaging, meeting the stringent requirements of pharmaceutical production. For example, in the packaging of tablets, the combination of breathability and water-repellent properties ensures that the drugs are protected from moisture during storage, maintaining their efficacy and quality.

3. Hospital Sterile Packaging

In hospitals, medical packaging paper is used for sterile packaging of surgical instruments, dressings, and other items. Its high strength and durability ensure that even in the high temperature and humidity environments of hospitals, the packaging paper maintains its protective properties, preventing contamination of instruments and dressings. In surgical dressing packaging, the use of high-strength kraft paper ensures that the dressing remains sterile until use, preventing infection.

4. IV Tube Tie Packaging

In the medical infusion field, this packaging paper is used to package IV tube ties. Its customizability and excellent adhesion ensure that IV tube ties remain secure during use, preventing them from slipping or loosening, and improving the safety and stability of infusions. In IV tube tie packaging, the customizable kraft paper can be precisely cut to the size and shape of the tie, ensuring a tight and secure package.

5. Band-Aid Packaging

In the production of bandages, medical packaging paper is used to package bandages. Its excellent breathability and waterproof properties ensure that bandages remain dry during use, promoting wound healing. Furthermore, its sterile and non-toxic properties prevent contamination after packaging, meeting the stringent requirements for medical products. In bandage packaging, the combination of breathability and waterproofing ensures that wounds can breathe while being protected from moisture, promoting rapid wound healing.

6. Mask Packaging

In mask production, this wrapping paper is used for mask packaging. Its customizability allows for precise size and shape customization for different mask models, ensuring a tight and protective packaging. Furthermore, its sterile and non-toxic properties ensure that masks remain sterile after packaging, preventing the spread of bacteria and viruses, meeting the stringent requirements for masks as epidemic prevention supplies. In the packaging of medical surgical masks, customizable kraft paper can be precisely cut to the size and shape of the mask, ensuring a tight and protective packaging.

Medical Packaging Paper Maintenance:

1. Store in a Dry Environment

Medical packaging paper should be stored in a dry, well-ventilated environment, away from water and moisture. It is recommended that packaging paper be stored on wooden or plastic pallets, at least 10 cm above the ground, to prevent the effects of ground moisture. The relative humidity in the warehouse should be maintained between 40% and 60%, and the temperature between 15°C and 25°C to ensure stable performance of the packaging paper.

2. Avoid Contact with Chemicals

During storage and use, packaging paper should be kept away from chemicals such as acids, alkalis, and oils to prevent corrosion or degradation. If packaging paper does come into contact with chemicals (such as for packaging certain specialty pharmaceuticals), small batch tests should be conducted to ensure chemical stability. During use, operators should wear protective gloves and masks to avoid direct contact with chemicals. Work areas should be cleaned and disinfected promptly after each operation to prevent potential damage to the packaging paper from residual chemicals.

3. Appropriate Stacking

Medical packaging paper should be stacked at a controlled height to avoid excessive stacking that could cause deformation or damage. Generally, a stacking height of no more than 1.5 meters is recommended. A "first-in, first-out" principle should be used when stacking to prevent degradation of the packaging paper's performance due to long-term storage. When stacking, place partitions between each layer to ensure stability. Use specialized handling tools during handling to prevent damage to the packaging paper due to improper handling.

4. Regularly Inspect Packaging Integrity

Regularly inspect the integrity of the packaging paper to ensure it is free of tears, cracks, or holes. If minor damage is found, repair it promptly with tape of the same material to prevent contaminants from entering. Severely damaged packaging paper should be replaced immediately to ensure the sterility and protective properties of the packaging. Establish a regular inspection system, using specialized inspection tools and equipment, to thoroughly inspect the appearance and performance of the packaging paper. Record inspection results and implement appropriate maintenance measures promptly.

5. Maintain a Clean Operating Environment

When handling medical packaging paper, the operating environment must be kept clean and hygienic. Operators should wear gloves and masks to avoid direct contact with the packaging paper to prevent contamination. Furthermore, the operating area should be regularly cleaned and disinfected to ensure sterility during the packaging process. During the cleaning process, special cleaning agents and disinfectants should be used and the prescribed procedures and methods should be followed to ensure the cleanliness and sterility of the operating environment.

Medical Packaging Paper FAQs:

1. Is the Medical Packaging Paper safe for direct contact with medical devices or wounds?

The tape is made of high-quality kraft paper which is self-evidently sterilised, non-toxic and is free from any hazardous chemicals thus it is safe to be used on adhesive bandages, sensitive medical applications, wound dressings etc.

2. Can Medical Packaging Paper maintain its performance in humid or sterile environments?

Yes. Our White Medical Packaging Paper is engineered for durability and consistent performance, even in challenging environments such as humid or sterilized conditions.

3. What are the Uses of Medical Packaging Paper?

The tape is commonly used in healthcare for sealing adhesive bandages, securing IV tubes and catheters, and packaging surgical instruments or pharmaceutical products.