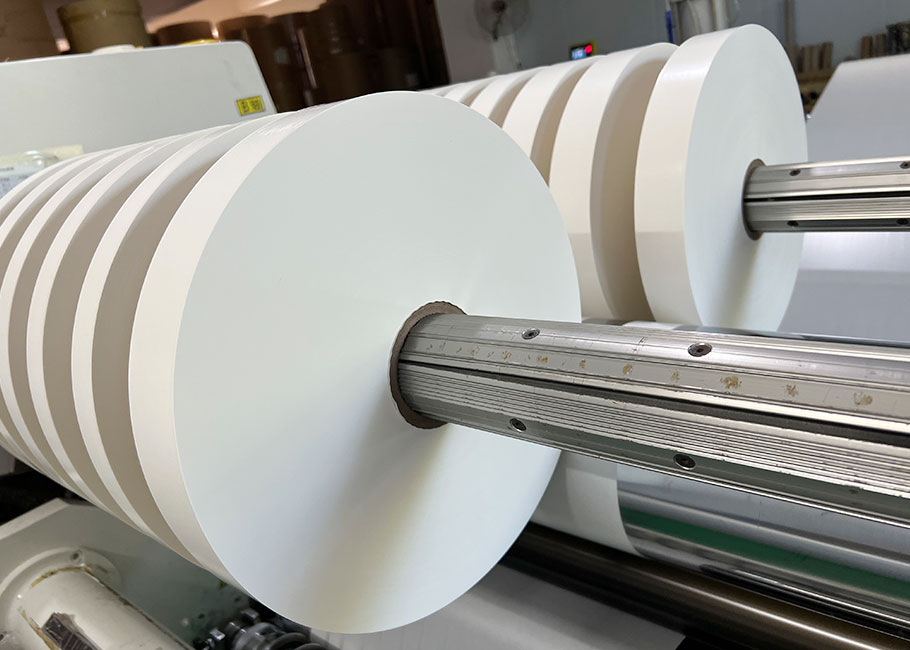

Medical Wrapping Paper

- Product Information

Medical Wrapping Paper is a material specially used for packaging medical supplies. It is mainly made of Kraft Paper and is processed through a special process to meet the medical industry's strict requirements for sterility and non-toxicity of packaging materials. It can provide effective protection and isolation for medical supplies to prevent them from being contaminated by the outside world, and ensure the safety and hygiene of medical supplies during production, transportation, storage and use. It is commonly found in hospitals, pharmaceutical factories and other places.

Medical Wrapping Paper Parameters:

| Material: | Kraft Paper |

| Size: | Customizable Width And Thickness According To Customer Requirements |

| OEM: | OEM/ODM Available |

| Packaging: | Carton |

| Factory Nature: | China Manufacturers Suppliers Factory |

Medical Wrapping Paper Features:

Thick and strong: Medical Wrapping Paper can be as thick as 0.15-0.3 mm, which is significantly better than conventional paper. Its mass per unit area is between 50-120 g/m2, which can provide a solid physical protection barrier for medical supplies. When subjected to external pressure or collision, it can effectively prevent the packaging of medical supplies from breaking, reducing the risk of damage during transportation and storage by more than 80%. For example, when packaging heavier surgical instrument boxes, thick paper can ensure that the instruments are not damaged due to packaging deformation during transportation and stacking, ensuring the integrity of medical supplies.

Extremely high strength: Tensile strength is a key indicator to measure the performance of Medical Wrapping Paper. The longitudinal tensile strength can reach 15-25 MPa, and the transverse tensile strength is also 10-18 MPa. This means that even when wrapping irregularly shaped or heavy medical supplies, the paper is not easily stretched, deformed or torn. In actual tests, it can withstand a tensile force of more than 50 times its own weight without breaking. For example, when packaging a box of 2 kg of medical consumables, the paper can easily withstand the vertical pulling force to ensure the firmness of the packaging.

Excellent breathability: The air permeability coefficient is 50 - 150 (unit: cm²・mmHg/(m²・s・kPa)), with good breathability. This allows the medical supplies in the package to maintain a suitable dry environment, control the humidity in the ideal range of 30% - 50%, and inhibit bacterial growth. During the sterilization process, such as ethylene oxide sterilization, it can allow the sterilization gas to efficiently penetrate the packaging material, and the sterilization efficiency is increased by 60% - 70%, ensuring that the medical supplies are completely sterile.

Excellent water absorption: The water absorption rate can reach 15% - 30%, which can effectively absorb external moisture and prevent liquid water from penetrating into the interior of the package. In a high humidity environment with a relative humidity of 90%, after 24 hours of testing, the surface of Medical Wrapping Paper was only slightly moist, and there was no obvious water seepage, and the internal medical supplies remained dry. This can avoid problems such as drugs becoming ineffective due to moisture and equipment rusting, and extend the shelf life of medical supplies.

Stable chemical properties: The chemical properties are stable within a wide range of pH values of 6-8. After 24 hours of contact with common disinfectants such as 75% medical alcohol and iodine tincture, the paper has no abnormal phenomena such as discoloration and deformation, and will not release harmful substances to contaminate medical supplies. In drug packaging, it can be in long-term contact with various drug ingredients without chemical reactions, ensuring the stability of drug quality.

Wide temperature resistance range: The temperature resistance range is wide and can be used normally at extreme temperatures from -40℃ to 120℃. When medical samples are stored in low-temperature freezing, the packaging paper will not crack; in high-temperature steam sterilization (121℃, maintained for 15-20 minutes), it will not soften, deform or degrade. After repeated high and low temperature cycle tests (-20℃ to 80℃, 100 cycles), the paper can still maintain its original protective properties, ensuring the safety of medical supplies in different storage and use scenarios.

Natural and environmentally friendly material: Natural kraft paper is the main material, and the degradability rate is as high as over 95%. In the natural environment, it can be completely degraded into carbon dioxide and water after 6-12 months, without pollution to soil and water sources. Its production process adopts environmentally friendly technology, which reduces production energy consumption by 40% and carbon emissions by 50% compared with plastic packaging materials, meeting the environmental protection requirements of sustainable development in the medical industry.

Good flexibility: Medical Wrapping Paper has good flexibility and can be folded more than 100 times without breaking. This enables it to flexibly fit the contour of the item and wrap tightly when packaging medical supplies with complex and irregular shapes. For example, when packaging surgical sutures, it can be easily folded and shaped to ensure that each suture is properly protected without affecting the convenience of unpacking during subsequent use.

Accurate custom size: The material width can be customized to 10-100 cm according to customer needs, and the thickness can be adjusted within the range of 0.1-0.5 mm. The dimensional accuracy is controlled within ±0.5 mm to meet the packaging specifications of different medical supplies. Whether it is small medical devices such as dental tools or large equipment such as surgical instrument kits, it can provide precise and suitable packaging dimensions to improve packaging efficiency and sealing.

Medical Wrapping Paper Applications:

Medical device packaging: Medical Wrapping Paper can be used for packaging of various medical devices such as surgical instruments, syringes, catheters, etc. For example, in the packaging of surgical instruments, it can prevent the instruments from being contaminated by external microorganisms, ensure the sterility of surgical use, and protect the hygiene of the instruments from storage before surgery to use in the operating room.

Pharmaceutical packaging: Suitable for the outer packaging of tablets, capsules, potions and other drugs. Taking the packaging of potion bottles as an example, Medical Wrapping Paper wrapped outside can not only prevent the potion bottles from collision and breakage, but also isolate external moisture and dust, maintain the quality of potions, and facilitate the storage and transportation of drugs.

Medical consumables packaging: Medical consumables such as Band-Aids, gauze, and infusion tube ties can be ensured to be sterile with the help of Medical Wrapping Paper packaging. For example, Band-Aids are easy to carry with you after packaging. They can be directly torn open and used, which is hygienic and convenient.

Medical sample container packaging: Container packaging such as test tubes and sample boxes used to hold medical samples. For example, when transporting samples, wrapping paper can cushion the bumps during transportation, prevent sample containers from being damaged, and isolate external contamination to ensure the accuracy of sample testing.

Medical protective equipment packaging: For protective clothing, masks, gloves and other protective equipment, Medical Wrapping Paper packaging can keep them clean and sterile. For example, when protective clothing is stored and transported, it can be wrapped to resist external dirt and germs, and medical staff can quickly put it on and start work.

Medical Wrapping Paper Maintenance:

Storage environment control: Medical Wrapping Paper should be stored in a dry and ventilated warehouse with a temperature of 15-25℃ and a humidity of 40%-60%. Avoid direct sunlight and place it away from the ground and the wall to prevent ground moisture and wall moisture from invading. This can prevent the packaging paper from getting damp and deteriorating and maintain its stable performance. For example, if it is stored on a shelf, the bottom of the shelf should be at least 20 cm from the ground and more than 30 cm from the wall.

Cleaning and maintenance: In daily use, you can use a soft brush to gently clean the surface dust. If it is stained, wipe it with a slightly damp (water content less than 30%) soft cloth. After wiping, dry it naturally. Do not rinse or soak it with water to avoid damaging the paper structure and affecting its strength and protective performance.

Anti-ultraviolet radiation: Long-term ultraviolet radiation will make the paper age and become brittle. Therefore, avoid ultraviolet sources during use and storage. If direct sunlight cannot be avoided, use a blackout curtain to block it, or store it deep in the warehouse without direct sunlight to reduce the damage of ultraviolet rays to the packaging paper.

Avoid contact with chemicals: Stay away from highly corrosive chemicals such as acids and alkalis, as well as organic solvents. If accidentally contaminated, wipe it clean with a damp cloth immediately and check whether the packaging paper is damaged. Once damage is found, replace the packaging in time to prevent harmful substances from contaminating the internal medical supplies through the packaging paper.

Regular inspection: Check the appearance and performance of the packaging paper at least once a week to check whether there are scratches or damage on the surface, whether the paper is yellowed or brittle, etc., and preliminarily judge the performance through a simple tensile test (pulling it by hand to feel the toughness). If problems are found, deal with them in time to ensure that they are in good and usable condition at any time.

Reasonable handling: Handle it with care when handling, avoid violent throwing and dragging. It is best to use containers such as cartons for handling to reduce human damage caused by direct contact. For paper that has been packaged with medical supplies, protection can be done in advance before handling, such as wrapping a layer of protective film on the outside to reduce the damage rate during handling.

Medical Wrapping Paper FAQs:

1. Is the Medical Wrapping Paper safe for direct contact with medical devices or wounds?

The tape is made of high-quality kraft paper which is self-evidently sterilised, non-toxic and is free from any hazardous chemicals thus it is safe to be used on adhesive bandages, sensitive medical applications, wound dressings etc.

2. Can Medical Wrapping Paper maintain its performance in humid or sterile environments?

Yes. Our Medical Wrapping Paper is engineered for durability and consistent performance, even in challenging environments such as humid or sterilized conditions.

3. What are the Uses of Medical Wrapping Paper?

The tape is commonly used in healthcare for sealing adhesive bandages, securing IV tubes and catheters, and packaging surgical instruments or pharmaceutical products.