High Quality Lithium Ion Battery Separator

- Product Information

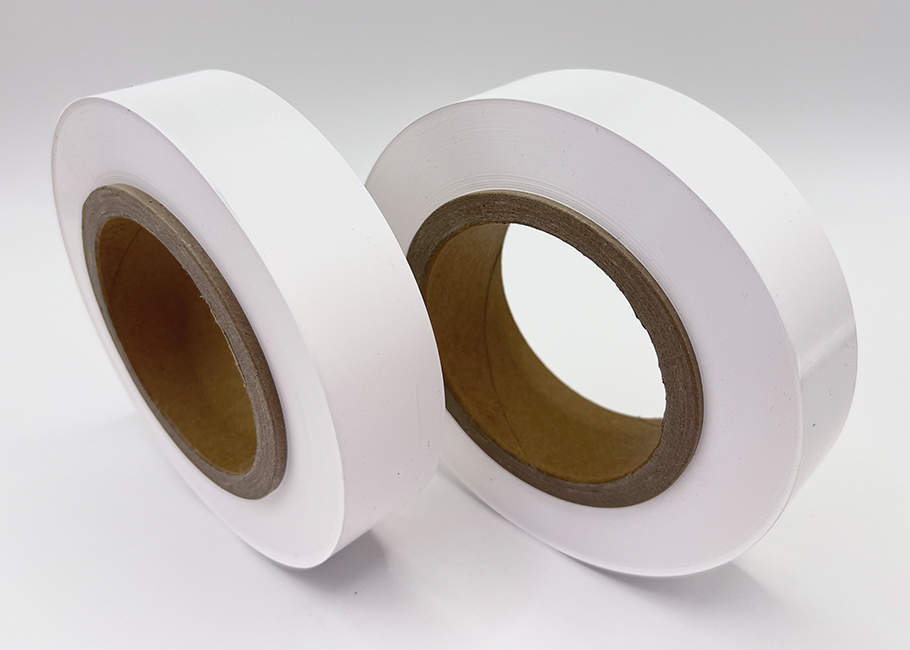

Lithium Ion battery separator is a key battery component made of polypropylene (PP) and polyethylene (PE) materials. It is usually in the form of a white roll with a thin thickness, a delicate texture and a uniform surface. In actual use, the separator is installed between the positive and negative electrodes of the lithium-ion battery to isolate the electrodes and prevent short circuits. In addition, the separator has a simple installation process and strong compatibility, and is suitable for various types of lithium-ion batteries. This separator is easy to process and cut, which can meet the efficiency requirements of large-scale production while also reducing production costs.

Lithium Ion battery separator Parameters:

| Material: | Polypropylene (PP) And Polyethylene (PE) |

| Dimensions: | Customizable Material Width And Thickness According To Customer Requirements |

| OEM: | OEM/ODM Available |

| Packaging: | Carton (should Not Be Subjected To Impact) |

Lithium Ion Battery Separator Features:

1. High electronic insulation

Lithium Ion Battery Separator has excellent electronic insulation performance, which can effectively prevent direct conduction of electrons between the positive and negative electrodes, thereby avoiding the occurrence of short circuits. According to the International Electrotechnical Commission (IEC) standard test, its insulation resistivity can reach more than 1×10^16 Ω·cm. This high insulation ensures that the electrochemical reaction inside the battery is carried out only through ion migration, maintaining the normal working state and energy conversion efficiency of the battery. During the battery charge and discharge cycle, the insulation performance of the separator remains stable, and the insulation performance will not decrease even under high voltage and high current conditions, providing reliable guarantee for the long-term stable operation of the battery.

2. High porosity structure

Lithium Ion Battery Separator has the characteristics of high porosity, usually between 40% - 50%. These microporous structures provide sufficient migration channels for lithium ions, allowing lithium ions to quickly shuttle between the positive and negative electrodes, thereby improving the charge and discharge efficiency of the battery. After professional testing, the average pore size of the diaphragm can be controlled within the range of 0.1-0.3 microns, and the pore size distribution is uniform, ensuring the consistency and stability of lithium ion migration. This combination of high porosity and suitable pore size enables the battery to maintain good performance at high-rate charge and discharge, effectively shortening the charging time and improving the power output capacity of the battery.

3. Excellent tensile strength

The lithium-ion battery diaphragm exhibits excellent tensile strength, with a longitudinal tensile strength of more than 120 MPa and a transverse tensile strength of more than 80 MPa. This feature enables it to withstand various mechanical stresses during battery manufacturing and use, including winding, assembly, and battery expansion. High tensile strength ensures that the diaphragm maintains a stable shape inside the battery and will not deform or rupture due to external forces, thereby maintaining the integrity of the internal structure of the battery. Even when the battery is subjected to a certain degree of external force impact, the diaphragm can still maintain its function, prevent the occurrence of internal short circuits, and improve the safety and reliability of the battery.

4. High puncture strength

The Lithium Ion Battery Separator has high puncture strength and can resist puncture from tiny particles inside the battery or the edge of the electrode. Test data shows that its puncture strength can reach more than 0.8 N/μm. This is crucial for the long-term stability of the battery, because during the production and use of the battery, it is inevitable that there will be some tiny foreign matter or sharp parts of the electrode material that pose a potential threat to the separator. High puncture strength ensures that the separator will not be easily damaged when facing these tiny puncture risks, thereby effectively preventing internal short circuits in the battery and corresponding safety issues, and extending the service life of the battery.

5. Good chemical stability

The separator exhibits good chemical stability in an organic electrolyte environment. After a long immersion test (more than 1000 hours), its physical and chemical performance retention rate is more than 95%. This means that the separator can be in contact with the electrolyte in the battery for a long time without chemical reaction or performance degradation, ensuring the stability and consistency of the battery during the charge and discharge cycle. This chemical stability is critical to the life and safety of the battery, especially the ability of the separator to consistently perform its isolation and support functions throughout the battery's life cycle.

6. Excellent thermal stability

The separator has excellent thermal stability and can maintain its structure and performance over a wide temperature range. Tests have shown that the shrinkage of the separator is less than 5% in the temperature range of -40°C to 85°C. This thermal stability ensures that the battery can still work normally under extreme temperature conditions, and the separator will not shrink, deform or melt due to temperature changes, thereby avoiding internal short circuits and other thermal runaway problems in the battery. This is especially important for equipment such as electric vehicles that need to operate in a variety of ambient temperatures, and can ensure the safety and reliability of the battery system.

Lithium Ion Battery Separator Application:

1. New energy vehicle field

In the field of new energy vehicles, lithium-ion battery separators are one of the core components of electric vehicle battery packs. According to industry research data, each electric vehicle requires an average of about 5-10 square meters of separators. The application of this separator significantly improves the energy density and safety of the battery, allowing electric vehicles to achieve longer driving range and faster charging speeds. For example, in the battery systems of some well-known brands of electric vehicles, the energy density of the battery pack has increased by 15% and the charging time has been shortened by 30% after the use of high-performance separators. In addition, the excellent thermal stability of the separator ensures the safe operation of electric vehicles in high temperature environments, reduces the risk of thermal runaway, and improves the safety performance of the entire vehicle.

2. Energy storage system field

In energy storage systems, lithium-ion battery separators are widely used in large-scale energy storage power stations and household energy storage devices. Energy storage systems require high-capacity, high-safety and long-life batteries, and the high-performance characteristics of the separator just meet these requirements. According to market research, the thickness of lithium-ion battery separators used in energy storage systems is usually between 12-16 microns to balance mechanical strength and ion conductivity. For example, in large-scale energy storage power station projects, the use of diaphragms with specific specifications has extended the battery cycle life by 20% and increased the energy conversion efficiency by 10%. This not only reduces the total cost of ownership of the energy storage system, but also improves its economy and reliability in applications such as grid peak regulation and renewable energy storage.

3. Consumer electronics

In the consumer electronics field, lithium-ion battery diaphragms are widely used in portable devices such as smartphones, tablets, and laptops. As the requirements for battery life and fast charging capabilities of electronic products continue to increase, the application of high-performance diaphragms has become crucial. For example, in the brand's flagship smartphones, the use of new diaphragms has increased the battery charging speed by 40%, while the battery thickness has been reduced by 15%, achieving thinness and high performance of the device. In addition, the high chemical stability of the diaphragm ensures the safety of the battery during long-term use and reduces the risk of equipment damage due to battery failure.

4. Aerospace

In the aerospace field, lithium-ion battery diaphragms are used in high-tech equipment such as satellites, drones, and avionics. These devices have extremely high requirements for battery performance and safety, and the excellent properties of the diaphragm enable it to meet these stringent requirements. For example, in the battery system of satellites, the use of specially treated diaphragms improves the performance stability of the battery in the extreme temperature environment of space (-150℃ to 120℃) by 35% and extends the service life by 2 times. In addition, the lightweight characteristics of the diaphragm help reduce the weight of the equipment and improve fuel efficiency, which is particularly important in the aerospace field.

5. Medical equipment field

In the field of medical equipment, lithium-ion battery diaphragms are widely used in portable medical devices, wearable medical monitoring devices and electric medical instruments. For example, in portable cardiac defibrillators, the use of high-performance diaphragms extends the discharge time of the battery by 25%, ensuring the reliable operation of the equipment in emergency situations. In addition, the biocompatibility and high safety of the diaphragm enable it to meet the strict requirements of medical equipment for batteries, reducing the risk of battery-related complications that may occur during the use of the equipment. According to industry statistics, the annual demand for lithium-ion battery diaphragms in the global medical equipment market is about 30 million square meters, and this demand will continue to grow with the continuous advancement of medical technology and the popularization of telemedicine equipment.

6. Industrial equipment

In the field of industrial equipment, lithium-ion battery separators are widely used in equipment such as power tools, automated robots, and backup power systems. These devices usually require batteries with high power density and long life, and the high performance characteristics of the separator can meet these requirements. For example, in the battery of power tools, the use of new separators has increased the power output of the battery by 30% and the working efficiency of the tool by 20%. In addition, the high mechanical strength and thermal stability of the separator ensure the reliability and safety of the battery in industrial environments, and can withstand frequent charge and discharge cycles and complex working conditions.

Lithium Ion Battery Separator Maintenance:

1. Storage environment control

Lithium Ion Battery Separator should be stored in a dry, cool and ventilated environment, with the temperature controlled at 20-25℃ and the humidity maintained at 40%-60%. Such environmental conditions can effectively prevent the separator material from absorbing moisture, deforming or performance degradation during storage. According to the material property test, the physical and chemical properties of the separator can be retained at more than 98% under a suitable storage environment. If the humidity of the storage environment is too high, the separator may absorb moisture, resulting in changes in pore size and decreased ion conductivity, which in turn affects battery performance. Therefore, it is recommended to store the separator in a dedicated storage room equipped with dehumidification equipment and a temperature and humidity monitoring system, and regularly check the storage conditions to ensure that the quality of the separator is not affected.

2. Avoid mechanical damage

During handling and storage, the separator should be protected from mechanical damage such as squeezing, folding or scratching. Although the material of the separator has a certain mechanical strength, it may still be damaged by external forces. For example, when the separator is subjected to a pressure of more than 50 N, local deformation or tiny cracks may occur. These damages may gradually expand during the use of the battery, resulting in battery performance degradation or safety problems. Therefore, when transporting the separator, special handling tools should be used, and the separator should be handled with care to avoid stacking too high. When storing, the separator should be placed on a flat shelf to avoid folding or bending. Check the appearance of the separator regularly. If there are signs of mechanical damage, it should be treated or replaced in time to ensure the integrity and performance of the separator.

3. Prevent chemical corrosion

Lithium Ion Battery Separator should avoid contact with organic solvents, acids and alkalis and other chemicals. If accidentally contacted, it should be immediately rinsed with plenty of water and performance tested. For example, after contact with certain organic solvents, the separator may swell or dissolve, resulting in damage to the pore structure and loss of performance. According to the chemical compatibility test, the physical properties of the separator can decrease by 30% - 50% after contact with common organic solvents (such as esters and ethers) for 24 hours. Therefore, during battery manufacturing and use, it should be ensured that the diaphragm is in contact with suitable electrolytes and battery materials to avoid the introduction of other chemicals. When cleaning the diaphragm, a mild aqueous detergent should be used, and detergents containing strong acids, strong alkalis or organic solvents should be avoided. The diaphragm after use should be handled in accordance with relevant chemical management regulations to prevent pollution to the environment.

4. Reasonable inventory management

A reasonable inventory management system should be established to follow the first-in-first-out principle to ensure that the diaphragm is used within the validity period. Although the diaphragm has a long storage life, long-term storage may still have a certain impact on its performance. According to the accelerated aging test, the tensile strength of the diaphragm decreases by about 5% and the porosity changes by about 3% after two years of storage. Therefore, it is recommended to conduct a performance sampling of the stocked diaphragms every six months to ensure that their quality meets the requirements. For diaphragms approaching the storage period, priority should be given to their use, and performance evaluation should be performed before use. Through reasonable inventory management, the degradation of diaphragm performance caused by long storage time can be minimized to ensure the quality and efficiency of battery production.

5. Cleaning and maintenance

During the battery manufacturing process, the diaphragm should be kept clean and contamination should be avoided. The diaphragm should be surface treated with dedicated cleaning equipment on the production line to remove dust, fiber and other impurities. For example, dust particles on the surface of the diaphragm may form micro short-circuit points inside the battery, resulting in battery performance degradation or safety problems. According to industry standards, the particle contamination level on the surface of the diaphragm should be controlled above ISO level 5. During the battery assembly process, operators should wear clean gloves and work clothes to avoid body oil and sweat from contaminating the diaphragm. Clean and disinfect the production environment regularly to ensure the cleanliness of the diaphragm during the manufacturing process. For diaphragms that have been installed in the battery, disassembly and cleaning should be avoided unless they are operated in accordance with professional guidance during battery maintenance or recycling.

6. Use environment monitoring

During the use of the battery, the working environment conditions of the battery, including temperature, humidity and mechanical stress, should be monitored regularly. The performance of the diaphragm may change under different environmental conditions, affecting the normal operation of the battery. For example, when the working environment temperature of the battery exceeds 60℃, the diaphragm may shrink thermally, resulting in a short circuit inside the battery. The operating temperature range of the battery should be controlled between -20℃ and 60℃, and the operating humidity range should be controlled between 10% and 90%. In applications such as electric vehicles, a battery management system (BMS) should be equipped to monitor battery parameters such as temperature, voltage and current in real time, and take timely measures such as cooling, heating or power-off protection when environmental conditions exceed the safe range. By using environmental monitoring and management, the service life of the battery can be extended, the performance of the diaphragm can be ensured to be stable, and the safety and reliability of the battery system can be improved.

Lithium Ion Battery Separator FAQs:

What materials are used to manufacture your Lithium Ion Battery Separators?

Our Lithium Ion Battery Separators are developed from Polypropylene (PP) and Polyethylene (PE) that are highly resistant with enhanced electrical meltdowns, tensile loads and excellent burst strength.

Can the size and thickness of the Lithium Ion Battery Separators be customized?

Yes, our Lithium Ion Battery Separators thickness and width can be customized totally as per the demands and expectations of the customer.

How are the Lithium Ion Battery Separators prepared for transportation?

Lithium Ion Battery Separators are packed in cartons with the utmost care since it is important that the delivery make it without ruining the product. All necessary precautions are taken in handling the cartons so that the separators do not get broken during shifting.