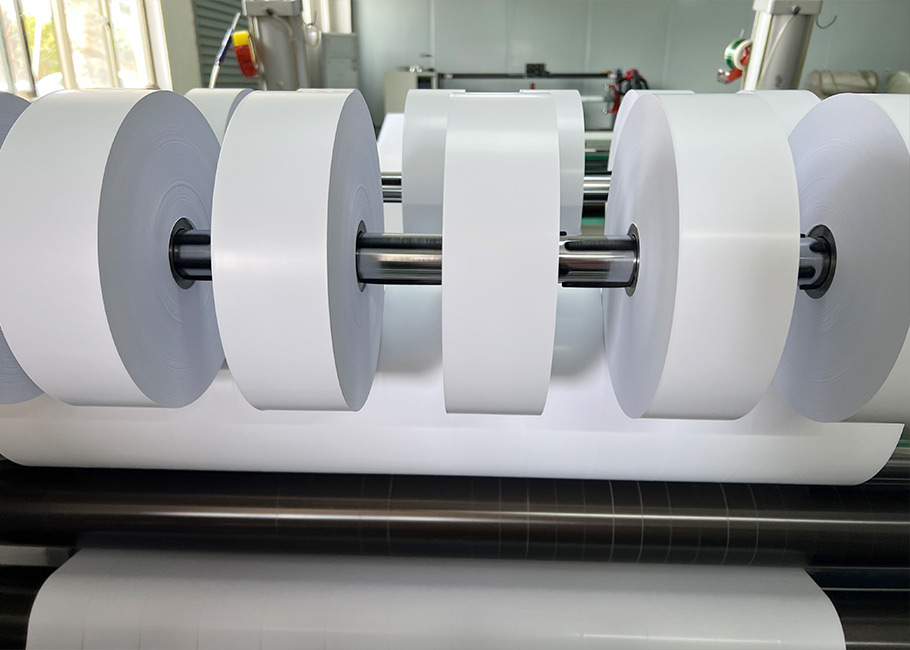

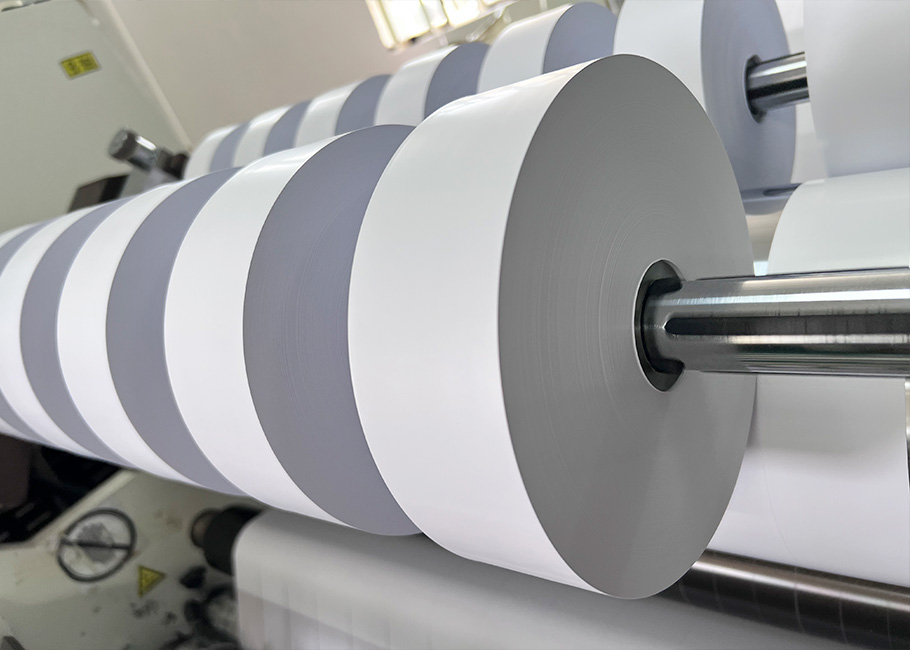

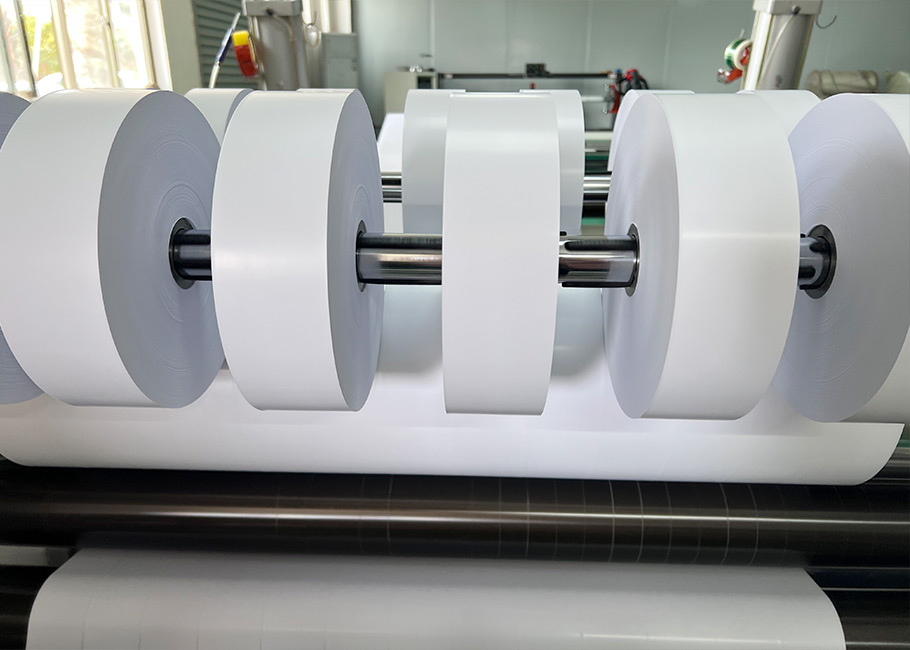

White Laminated Paper Roll

- Product Information

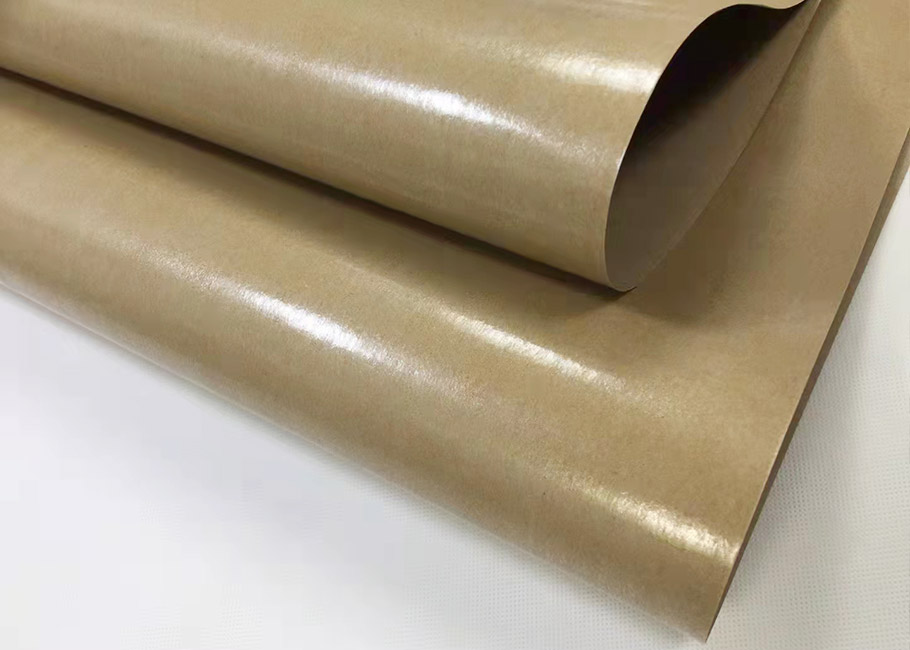

White Laminated Paper is a high-quality composite material composed of layers of paper and polyethylene (PE). This material combines the lightweight of paper with the water- and moisture-resistant properties of PE, offering a smooth surface, good tensile strength, and excellent strength. It provides a reliable and efficient solution for packaging and protection needs across a wide range of industries.

White Laminated Paper Parameters:

| Material: | Paper and PE |

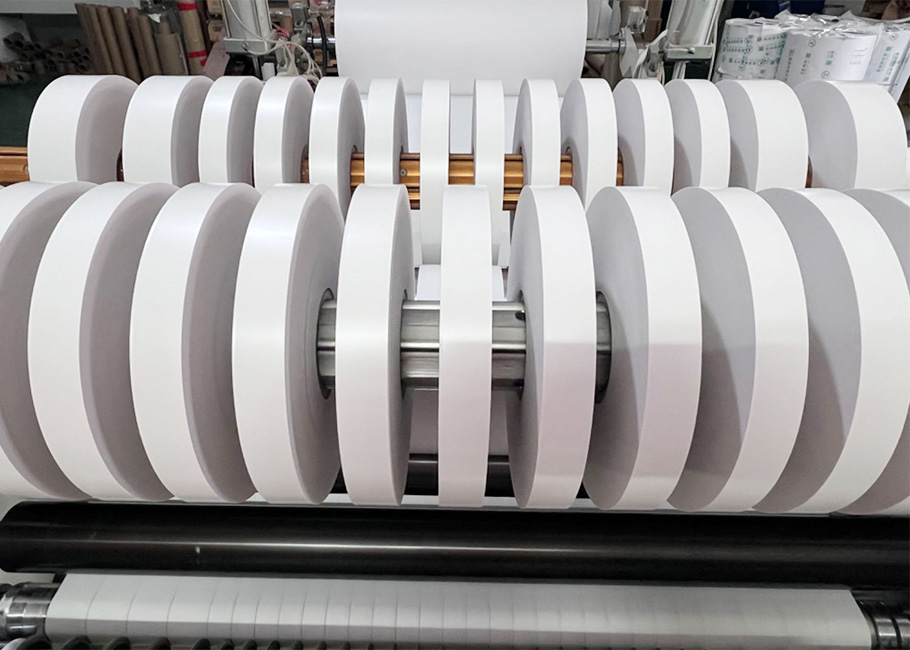

| Size: | Customizable Material Width And Thickness According To Customer Requirements |

| OEM: | OEM/ODM Available |

| Packaging: | Carton |

| Factory Nature: | China Manufacturers Suppliers Factory |

White Laminated Paper Features:

1. High-Quality Materials

White Laminated Paper is a composite of high-quality paper and polyethylene (PE). High-strength fibers are used in the paper to ensure its basic strength. The PE layer has a uniform thickness of approximately 0.03-0.05mm, imparting excellent water and moisture resistance. This composite process combines the lightness of paper with the durability of PE, making it suitable for a wide range of applications.

2. Excellent Tensile Strength

This material exhibits excellent tensile strength, with a tensile strength of 15-20N/15mm. Professional testing on a standard tensile testing machine has shown that its tensile strength is 3-4 times higher than that of ordinary paper. This strong tensile strength ensures that the material is resistant to breakage during use and can withstand high tensile forces, making it suitable for packaging and protective applications requiring high tensile strength.

3. High Strength

White Laminated Paper exhibits excellent strength, with a compressive strength of 30-35N/15mm. In actual use, pressure testing has shown that the material exhibits no noticeable deformation or damage, even under heavy loads. This high strength effectively protects its contents from damage caused by external forces during transportation and storage.

4. Waterproof and Moisture-Proof

The material exhibits excellent water and moisture resistance, with a water absorption rate of less than 0.1%. After 72 hours of storage at 95% relative humidity, its thickness expansion does not exceed 1%. This ensures that the material maintains excellent physical properties and appearance in humid or water-immersed environments, without loss of strength or wrinkling due to water absorption. It is suitable for applications requiring high moisture resistance.

5. Smooth Surface

White Laminated Paper has a smooth and even surface, with a smoothness of 200-250S (tested according to DIN 4768). This smooth surface not only enhances the material's appearance but also provides excellent performance during printing, writing, and contact with other materials. During the printing process, the smooth surface ensures even distribution of ink, improving print quality.

6. Environmental Performance

White Laminated Paper complies with multiple international environmental standards. Its paper is partially recyclable, and the PE layer uses environmentally friendly additives during production to ensure that no harmful substances are released during use. With a recyclability rate exceeding 85%, even after disposal, it has minimal impact on the environment, in line with modern environmental protection concepts.

White Laminated Paper Application:

1. Electroplating Industry

In the electroplating industry, white laminated paper is primarily used for packaging and isolating electroplated parts. Its waterproof and moisture-proof properties and high tensile strength effectively protect parts from moisture and chemical corrosion during the electroplating process, ensuring surface quality. Using white laminated paper, electroplating plants have reduced part surface defect rates from 8% to below 1%, reducing packaging costs by 30%, and significantly improving product quality and customer satisfaction.

2. Stamping Industry

In the stamping industry, this material is commonly used to protect and package stamped parts. Its high strength and flexibility withstand the mechanical stresses of the stamping process, protecting parts from collisions and scratches during stamping and transportation. In field tests, automotive parts manufacturers have seen a reduction in the damage rate of stamped parts during transportation from 5% to 0.5% after using white laminated paper to package stamped parts, significantly reducing production costs and defective product rates.

3. Electronic Hardware Industry

In the electronics and hardware industry, white laminated paper is widely used for packaging electronic components and hardware parts. Its smooth surface and environmentally friendly properties ensure that electronic components are not scratched or contaminated during the packaging process. Its waterproof and moisture-resistant properties effectively protect electronic components from humid environments. After using White Laminated Paper, electronics factories have seen a 60% reduction in component defect rates, significantly improved product performance stability, and enhanced market competitiveness.

4. Printing and Packaging Industry

In the printing and packaging industry, White Laminated Paper is suitable for producing high-quality printed materials and packaging materials. Its smooth surface and excellent printability ensure clear and vibrant printed images, enhancing product appearance and market appeal. Printing companies using White Laminated Paper have seen a 40% improvement in print quality, a 70% reduction in customer complaints, and a significant increase in product added value.

5. Pharmaceutical Industry

In the pharmaceutical industry, White Laminated Paper is used to protect pharmaceutical packaging and medical devices. Its environmentally friendly and waterproof properties meet the strict standards of the pharmaceutical industry, effectively preventing moisture-induced deterioration of pharmaceuticals and contamination of medical devices. After practical application testing, pharmaceutical companies have seen their pharmaceuticals' shelf life extended by six months after using White Laminated Paper for packaging, and the qualified packaging rate has increased by 90%, ensuring the quality and safety of the drugs.

6. Food Industry

In the food industry, White Laminated Paper is used as a barrier layer in food packaging. Its smooth surface and waterproof and moisture-proof properties prevent moisture and contamination, while its environmentally friendly properties prevent the migration of harmful substances into food. Food companies using White Laminated Paper have significantly improved the sealing and freshness of food packaging, extending the shelf life of food by 30% and significantly increasing customer satisfaction.

White Laminated Paper Maintenance:

1. Storage Environment Control

White laminated paper should be stored in a dry, well-ventilated environment, away from direct sunlight, high temperature, and high humidity. It is recommended that materials be stored on shelves at least 10 cm above the ground and away from water and heat sources. In the warehouse, materials should be sorted and stored by batch and specification for easy management and use. Regularly check the warehouse's temperature and humidity to maintain a temperature between 15°C and 25°C and a relative humidity between 40% and 60% to ensure stable material performance.

2. Prevent Mechanical Damage

During handling and use, materials should be protected from mechanical damage such as scratches, tears, and punctures. When transporting, use dedicated handling tools, such as a cart or forklift, to ensure smooth movement of materials and avoid collisions and drops. When stacking, control the stack height to prevent excessive pressure that could cause deformation or damage.

3. Prevent Chemical Contamination

White laminated paper should be protected from contact with harmful chemicals, such as strong acids, strong bases, and organic solvents. During use, ensure a clean working environment to prevent contamination of the material. If use in a chemical environment is necessary, appropriate protective measures should be taken, such as using a protective film or barrier layer.

4. Regularly Check the Condition of the Material

Regularly check the condition of the white laminated paper to ensure it has not been damaged or degraded during storage and use. Inspections should include the material's appearance, strength, and waterproof and moisture-proof properties. Perform a comprehensive inspection at least monthly, recording changes in the material's condition to promptly identify potential problems and take appropriate measures.

5. Cleaning and Maintenance

Maintaining the cleanliness of white laminated paper during use is crucial to ensuring its performance. Gently wipe the surface with a soft, dry cloth to remove dust and dirt. If the surface is oily or stubbornly stained, use an appropriate amount of neutral detergent, but avoid using excessive moisture to prevent the material's waterproof and moisture-proof properties from being affected. After cleaning, dry the material in a well-ventilated area. Ensure the surface is dry before packaging or storing.

6. Appropriate Use and Recycling

When using white laminated paper, cut and use it appropriately according to actual needs to avoid waste. Used materials should be sorted and recycled, and disposed of in accordance with local environmental regulations. The paper portion of this material is recyclable, and the PE layer can also be reprocessed through professional recycling channels, achieving resource recycling.

White Laminated Paper FAQs:

What is White Laminated Paper made of?

White Laminated Paper is made by laminating a layer of Polyethylene (PE) onto high-quality paper. Such combinations give better moisture, better strength, and better surface finish.

Is it possible to get a customized White Laminated Paper in the desired size?

Yes, we offer full customization of White Laminated Paper to meet your specific requirements. You can adjust the width and thickness of the paper to suit the scope of its utilization.

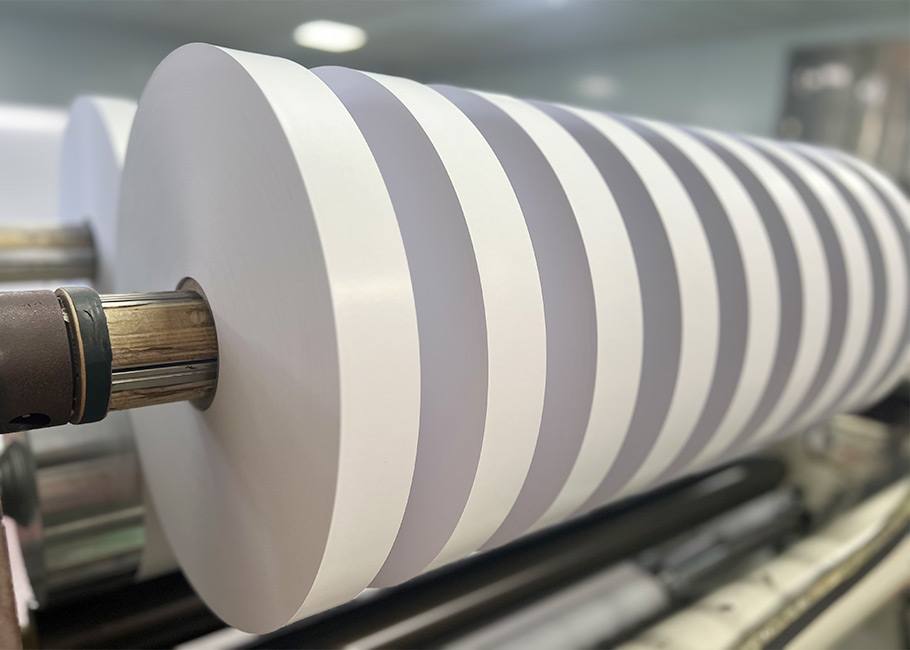

How should I keep White Laminated Paper in good condition?

In order to protect the quality and the properties of White Laminated Paper, it must be stored at controlled temperatures, in clean, dry conditions avoiding direct exposure to sun and humidity. Paper rolls should be kept on a flat surface in order to prevent bends and creases in the paper.