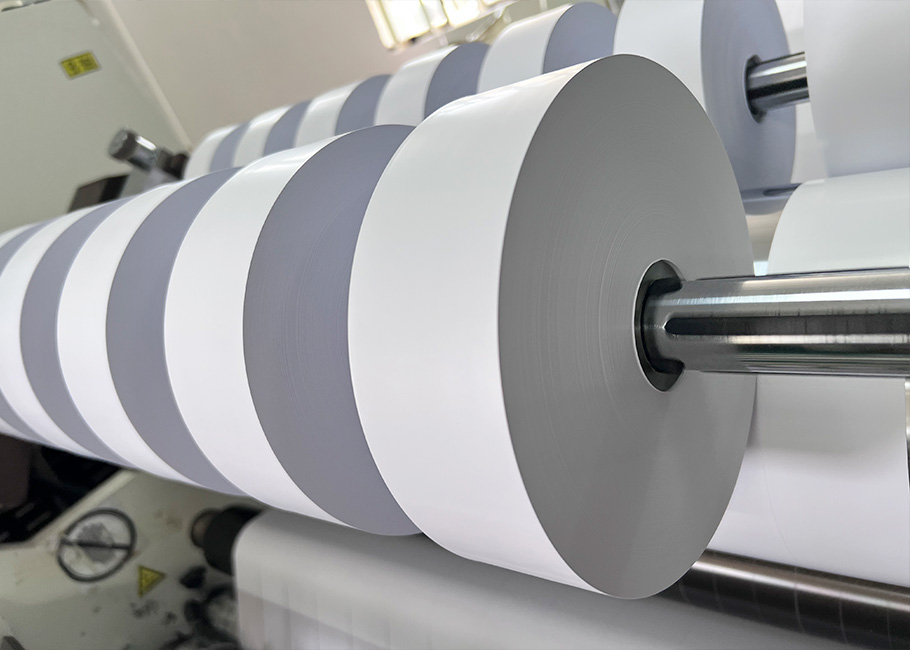

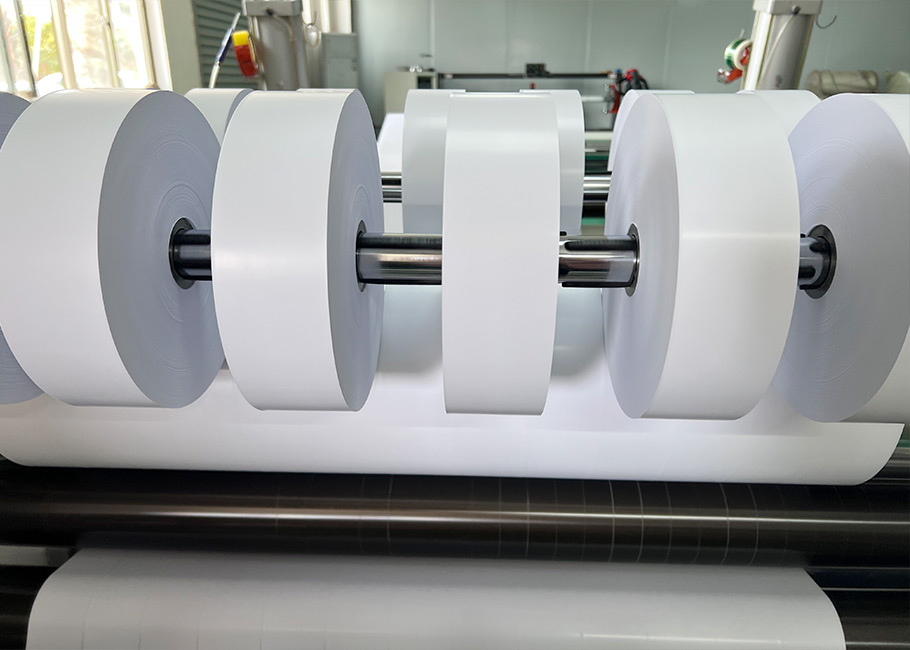

White Laminated Paper Roll

- Product Information

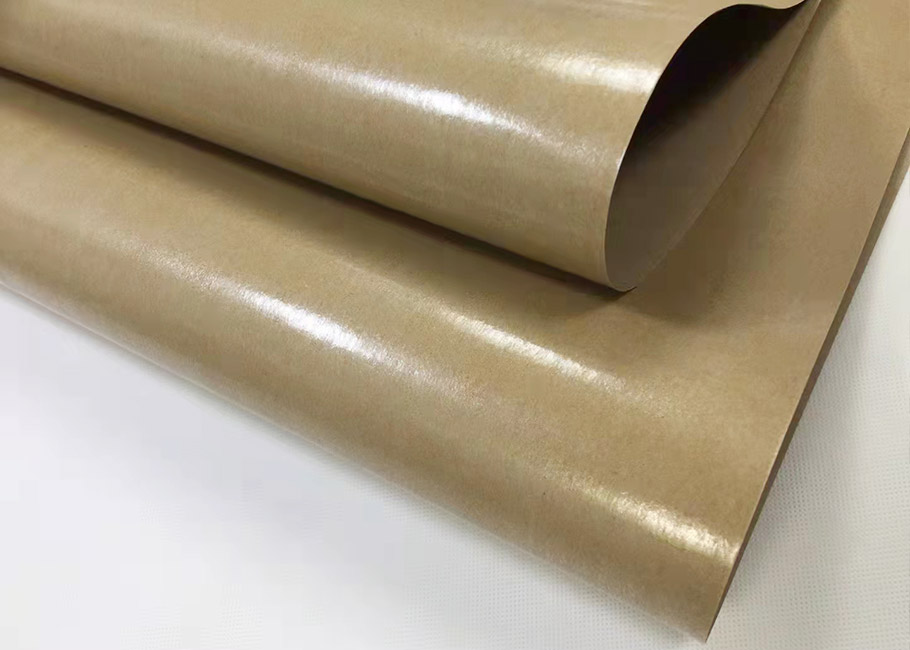

white laminated paper is an innovative composite material that deeply integrates paper and polyethylene (PE) materials through advanced composite technology. From the perspective of raw material composition, the paper base usually uses paper with certain fiber strength and flexibility. Its fiber structure provides basic support and processability for the composite paper, ensuring that the paper is not easy to tear during daily use and processing. The PE material is closely combined with the paper in the form of a special coating or lamination, giving the composite paper additional excellent properties.

White Laminated Paper Parameters:

| Material: | Paper and PE |

| Size: | Customizable Material Width And Thickness According To Customer Requirements |

| OEM: | OEM/ODM Available |

| Packaging: | Carton |

| Factory Nature: | China Manufacturers Suppliers Factory |

White Laminated Paper Features:

Good tensile strength: White Laminated Paper exhibits extremely excellent tensile performance. After strict testing by professional institutions in accordance with international standards, under specific test conditions, its longitudinal tensile force can reach more than 65N/15mm, and the transverse tensile force can also be stabilized at more than 50N/15mm. For example, in a tensile test simulating an actual use scenario, the white laminated paper is fixed on a special tensile test device, and the tensile force is gradually increased until the paper breaks, and the tensile value at the time of breakage is recorded. Multiple test results show that its average longitudinal tensile force reaches 68N/15mm, and the average transverse tensile force reaches 52N/15mm. Such excellent tensile performance enables it to maintain structural integrity and stability when subjected to large external tensile forces. In the logistics and transportation industry, when used to bundle and fix large goods, the goods will be subjected to tension and shaking in various directions during transportation. The good tensile performance of white laminated paper ensures the firmness of the bundle and prevents the goods from loosening, shifting or even being damaged. Take the transportation of large mechanical equipment as an example. The weight of the equipment can reach several tons. During the transportation process, it will experience complex road conditions such as bumps and turns. With its strong tensile force, the white composite paper can withstand the huge tensile force caused by the shaking of the equipment to ensure transportation safety. This is mainly due to the strong intermolecular force formed after the paper and PE material are compounded, as well as the fiber structure of the paper itself and the toughness of the PE material. They work together to give the composite paper excellent tensile resistance.

High strength: The strength performance of the composite paper is extremely outstanding. Its tear strength reaches a high level in both the longitudinal and transverse directions. The longitudinal tear strength can be as high as 20kN/m or more, and the transverse tear strength is more than 15kN/m. In the professional tear strength test, the white composite paper is tested using a standard tear test instrument according to the prescribed test method. The results show that the average longitudinal tear strength reaches 21kN/m, and the average transverse tear strength reaches 16kN/m. The high strength characteristics make it have excellent resistance to damage when facing external impact or friction. In the construction industry, white composite paper can be used for temporary protection of walls, floors, etc. During the construction process, the on-site environment is complex, and personnel and equipment move frequently, which can easily cause collisions and friction on protective materials. For example, when construction workers are carrying construction materials, they may accidentally hit the protective white laminated paper, but due to its high strength, it can effectively resist these external forces and protect the building surface from damage. This is mainly because its composite structure makes the material have uniform and good mechanical properties in all directions, which can disperse and withstand external forces, thereby improving the overall strength.

Waterproof and moisture-proof: Waterproof and moisture-proof is one of the core characteristics of White Laminated Paper. PE material itself has excellent waterproof properties, which makes the laminated paper have good water barrier properties. After rigorous waterproof testing, the water absorption rate of the white laminated paper sample was still less than 1% after being completely immersed in water for 72 hours. In a test simulating an extremely humid environment, the white laminated paper was placed in an environment with a relative humidity of up to 95% and a temperature of 40°C for 30 days. Its various performance indicators remained basically unchanged, and the weight increased by less than 0.5%. In a humid underground warehouse environment, items packaged with this laminated paper can effectively prevent the penetration of humid air and moisture. For example, for some metal products, humid environments can easily lead to rust and corrosion, while the waterproof and moisture-proof properties of white laminated paper can provide reliable protection for metal products and extend their service life. This is due to the tight molecular structure of PE materials, which can form an effective waterproof barrier to prevent moisture from entering the laminated paper.

Smooth: The surface smoothness of White Laminated Paper is extremely high, and its surface roughness Ra value can reach below 0.5μm. The white laminated paper was measured using a high-precision surface roughness measuring instrument and tested at multiple different locations. The results showed that its average surface roughness was 0.45μm. This smooth surface prevents it from causing any scratches on the surface of the protected object when it comes into contact with the protected object. In the optical lens industry, for high-precision optical lenses, even a tiny scratch will affect their optical performance. The smooth surface of white laminated paper can fit perfectly with the lens, providing all-round protection for the lens during transportation and storage, ensuring that the lens surface is not damaged. At the same time, the smooth surface also facilitates the unfolding and flattening of the paper, and can be operated quickly and smoothly on the automated packaging production line, improving production efficiency.

Good flexibility: The composite paper has good flexibility, and its bending radius can reach 5mm without breaking. In the flexibility test, the white composite paper was bent around cylinders of different diameters. When the diameter of the cylinder was 10mm (corresponding to a bending radius of 5mm), the paper did not crack or break. In practical applications, this flexibility allows it to easily adapt to the packaging of items of various shapes. For example, when packaging special-shaped crafts, the white composite paper can fit the contour of the crafts tightly and provide all-round protection. Moreover, it will not crack or break during repeated bending and folding, ensuring the integrity and reliability of the packaging. This flexibility is determined by the characteristics of paper and PE materials. The fiber structure of the paper provides a certain flexibility basis, and the addition of PE materials further enhances this flexibility, enabling it to meet complex packaging requirements.

Environmentally friendly and recyclable: White Laminated Paper has certain environmental protection and recyclability. With the continuous improvement of environmental awareness, the environmental performance of materials has received more and more attention. The paper part of the composite paper can be recycled and reused, and after professional processing, it can be remade into new paper products. According to relevant research data, recycling the paper part of 1 ton of white composite paper can produce about 0.8 tons of recycled paper after deinking, pulping and other processes. PE materials can also be recycled and reprocessed through specific recycling technologies to produce other plastic products. For example, some companies will recycle used white composite paper, separate the paper and PE materials, and recycle them separately, which reduces production costs and meets environmental protection requirements. In the circular economy model, the recycling of white composite paper can reduce resource waste and environmental pollution.

White Laminated Paper Application:

Electroplating industry: In the electroplating industry, White Laminated Paper has a wide range of important applications. The electroplating process has extremely high requirements for the humidity, cleanliness of the environment and the stability of the hanger. The waterproof and moisture-proof properties of the composite paper can prevent the electroplating solution from getting damp and deteriorating, ensuring the chemical properties of the electroplating solution are stable. At the same time, its good tensile force and strength enable it to firmly bind the electroplating hanger. In large-scale electroplating production lines, hangers need to be frequently moved between different electroplating tanks and bear the weight of the electroplated workpieces. For example, in a large hardware electroplating plant, thousands of hardware weighing 5-10 kg need to be processed every day, and the weight of the hanger is huge. The high-strength binding of white composite paper can ensure that the hanger will not loosen or break during long-term use, ensuring the accurate position of the electroplated workpiece, thereby obtaining a uniform and high-quality electroplating effect. According to actual production statistics, the use of white composite paper for hanger bundling can reduce the defective rate of electroplated workpieces by about 22%, greatly improving production efficiency and product quality.

Stamping industry: During the stamping process, the surface of the mold and the workpiece are easily damaged, and White Laminated Paper can play a key protective role. The composite paper is placed between the mold and the workpiece, and its high strength and smooth surface can withstand the huge pressure and friction during the stamping process. In the stamping production of automotive parts, the stamping of parts such as automotive body covers requires high-precision molds and good surface quality. For example, when stamping a car door, the stamping pressure can reach hundreds of tons, and the friction between the mold and the workpiece is extremely large. White laminated paper can effectively prevent defects such as scratches and indentations on the surface of the mold and workpiece, and ensure the appearance and dimensional accuracy of the parts. Moreover, its customized size can be precisely cut according to different molds and workpiece shapes to ensure that the area to be protected is fully covered during the stamping process to improve the protection effect. Using this composite paper for protection can increase the stamping pass rate of automotive parts by more than 20%, reducing production costs.

Electronic hardware industry: Electronic components and hardware products in the electronic hardware industry have strict requirements on environmental humidity and surface protection. The waterproof, moisture-proof and smooth properties of White Laminated Paper make it an ideal packaging material. For high-precision electronic chips, slight humidity changes and surface scratches may cause their performance to deteriorate or even be scrapped. The waterproof and moisture-proof properties of white laminated paper can keep electronic components dry and prevent short circuits due to moisture. For example, in some high-end electronic chip production workshops, the ambient humidity needs to be strictly controlled between 30% and 40%. After packaging with white laminated paper, it can effectively isolate the external humid air and ensure the humidity stability of the chip during storage and transportation. Its smooth surface will not scratch the surface of the component, ensuring the appearance and electrical performance of the component. During the transportation of electronic products, the use of this laminated paper packaging can reduce the damage rate of electronic products by more than 28%, improving the transportation safety and market competitiveness of the products.

Printing and packaging industry: In the field of printing and packaging, White Laminated Paper is mainly used for the isolation and protection of high-end printed products. For some exquisite picture albums, high-end gift boxes and other printed products, the surface quality requirements are extremely high. The smooth surface of the laminated paper can reduce the friction between the printed product and prevent scratches on the surface of the printed product. At the same time, its white appearance and good flatness can enhance the overall display effect of the printed product, making the printed product more beautiful and high-end. In the packaging of high-end cosmetics, the use of white laminated paper as a lining or isolation layer can provide good protection for the cosmetics, while enhancing the overall image of the product and increasing the added value of the product. Moreover, its customizable size and thickness can meet the packaging needs of printed materials of different specifications. According to market research, the market price of high-end printed materials packaged with white laminated paper can be increased by an average of 10% - 15%.

food packaging industry: White Laminated Paper also plays an important role in the food packaging industry. Its waterproof and moisture-proof properties can keep food dry and fresh, and prevent food from getting damp and deteriorating. For some dry snacks, tea and other foods, the use of this laminated paper for packaging can effectively extend the shelf life of the food. For example, for tea packaging, in an environment with a relative humidity of 60%, tea wrapped in ordinary paper may become damp and change taste after 3 months, while tea wrapped in white laminated paper can still maintain good quality after 6 months in the same environment. At the same time, the composite structure of paper and PE material gives the packaging a certain strength, which can protect the food from being squeezed and damaged during transportation and storage. Moreover, it can be customized according to the size and shape requirements of food packaging to ensure that the packaging fits perfectly with the food. In addition, as consumers pay more and more attention to food safety and environmental protection, the environmentally friendly and recyclable characteristics of the composite paper also meet market demand, providing a green and safe solution for food packaging.

Medical industry: In the medical industry, White Laminated Paper can be used for the packaging of medical devices and medicines. Medical devices have extremely high requirements for the cleanliness and protection of packaging materials. The smooth surface of the composite paper can reduce the adhesion of dust and microorganisms, and its waterproof and moisture-proof properties can protect medical equipment from the influence of humid environments and prevent equipment from rusting and damage. For pharmaceutical packaging, white composite paper can keep the drugs dry and ensure the chemical properties of the drugs are stable. In some pharmaceutical packaging that requires long-term storage, the use of this composite paper can effectively extend the shelf life of the drugs. For example, some biological agents need to be stored in a dry and sterile environment, and the waterproof, moisture-proof and clean properties of white composite paper can meet their packaging requirements. Moreover, its customizability can meet the packaging specifications of different drugs and medical devices, providing a safe and reliable packaging solution for the medical industry. According to feedback from medical institutions, the damage rate of medical equipment and medicines packaged in white composite paper during storage and transportation has been reduced by more than 18%.

White Laminated Paper FAQs:

What is White Laminated Paper made of?

White Laminated Paper is made by laminating a layer of Polyethylene (PE) onto high-quality paper. Such combinations give better moisture, better strength, and better surface finish.

Is it possible to get a customized White Laminated Paper in the desired size?

Yes, we offer full customization of White Laminated Paper to meet your specific requirements. You can adjust the width and thickness of the paper to suit the scope of its utilization.

How should I keep White Laminated Paper in good condition?

In order to protect the quality and the properties of White Laminated Paper, it must be stored at controlled temperatures, in clean, dry conditions avoiding direct exposure to sun and humidity. Paper rolls should be kept on a flat surface in order to prevent bends and creases in the paper.