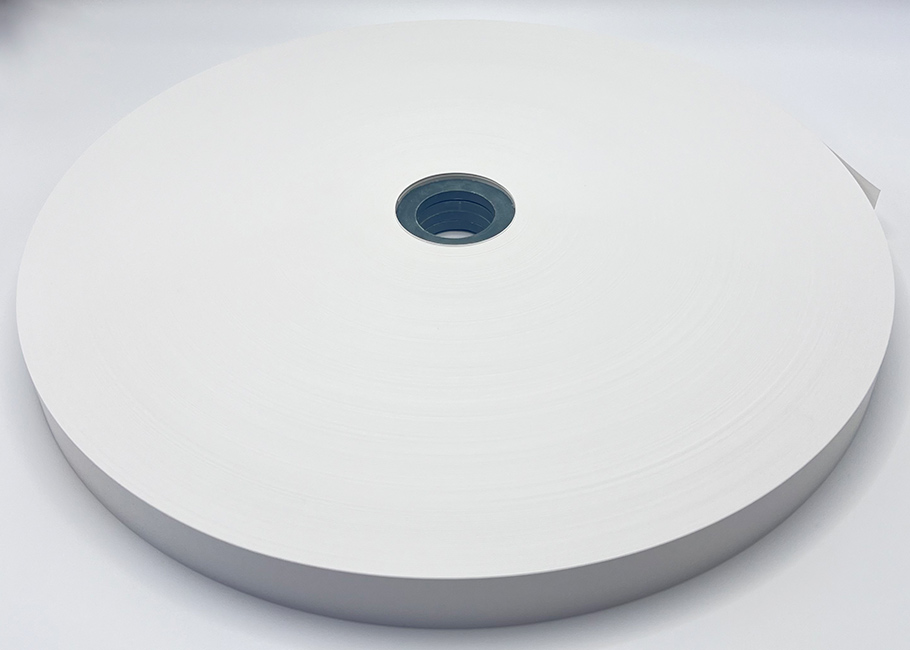

White Kraft Butcher Paper Roll

- Product Information

White Kraft Butcher Paper Roll is a high-quality Kraft Paper roll designed for industrial applications. Made of white kraft paper, it is finely processed and has excellent strength, flexibility and isolation properties. This paper roll is mainly used in electroplating, stamping, electronic hardware, printing and packaging industries to provide reliable isolation and protection for various industrial products during production, processing, transportation and storage.

White Kraft Butcher Paper Roll Parameters:

| Material: | Kraft Paper |

| Size: | Customizable Material Width And Thickness According To Customer Requirements |

| OEM: | OEM/ODM Available |

| Packaging: | Carton |

| Factory Nature: | China Manufacturers Suppliers Factory |

White Kraft Butcher Paper Roll Features:

Excellent Isolation Effect

White Kraft Butcher Paper Roll performs well in the electroplating industry, effectively isolating metal workpieces to prevent adhesion and contamination. After testing, the surface defect rate of workpieces isolated by this paper tape on the electroplating line was reduced by 30%-40%. This not only improves the appearance of the product, but also enhances performance, reduces rework and material waste, and helps companies control costs and improve production efficiency. Its isolation effect remains stable in high temperature, high humidity and chemical environments, ensuring product quality consistency.

Strong Tensile Strength

White Kraft Butcher Paper Roll has an extremely high tensile strength of 1500-2000 N/50mm, far exceeding the 800-1200 N/50mm of ordinary paper tape. In the stamping industry, it can withstand the strong pressure and tension in the stamping operation, effectively prevent breakage, and ensure production continuity. For example, when stamping large metal parts, paper tape can firmly bundle and isolate the workpiece, reduce the risk of damage, improve the yield rate, and reduce corporate costs.

High flexibility and folding resistance

White Kraft Butcher Paper Roll has excellent flexibility and folding resistance. In the folding test, it can withstand 1,000 folds without breaking, while ordinary paper tape will break after 300-500 folds. In the electronic hardware industry, facing irregularly shaped electronic components and hardware parts, this high flexibility enables it to fit tightly, provide all-round isolation protection, reduce collision damage during transportation and storage, and ensure product integrity.

Good chemical corrosion resistance

In an acid-base environment with a pH value of 2-12, the physical properties of White Kraft Butcher Paper Roll decrease by less than 10%, while the performance of ordinary paper tape under the same conditions can decrease by 30%-50%. In the chemical processing and electroplating industries, it can effectively resist chemical corrosion, extend service life, ensure that workpieces are not contaminated during processing and transportation, maintain high quality standards, and reduce corporate costs.

Highly efficient moisture absorption performance

In a high humidity environment of 80%-90% relative humidity, the moisture absorption of White Kraft Butcher Paper Roll can reach 10%-15% of its own weight. In the printing and packaging industry, it can effectively reduce the risk of moisture in printed products and ensure printing quality. For example, paper and printed products are prone to absorb moisture under high humidity, resulting in deformation and staining. After using this paper tape for isolation, the quality of printed products is stable, the defective rate is greatly reduced, and the production efficiency and corporate economic benefits are significantly improved.

Customizable width and thickness

White Kraft Butcher Paper Roll provides flexible customization services with a width range of 10-100 mm and a thickness range of 0.1-0.3 mm. In the electronic hardware industry, customized paper tapes can accurately meet the needs of electronic components and hardware parts of different sizes. For example, small electronic components require refined isolation, while large hardware parts require thicker and wider paper tapes. This customized service improves production efficiency, reduces material waste, optimizes production processes, and enhances corporate market competitiveness.

Safe and non-toxic industrial-grade material

White Kraft Butcher Paper Roll is made of safe and non-toxic industrial-grade kraft paper, which meets strict industrial safety standards and does not contain harmful substances such as heavy metals and plasticizers. During use, it will not release toxic substances, ensure the health and safety of operators, and will not pollute the environment. For example, in a poorly ventilated workshop, the use of inferior toxic paper tape may endanger the health of workers, but this paper tape eliminates such risks, helping companies to create a safe working environment and meet environmental protection and occupational health requirements.

Environmentally friendly and recyclable characteristics

The kraft paper material of White Kraft Butcher Paper Roll comes from sustainably managed forests and can be fully recycled and reused. Compared with traditional plastic isolation materials, it degrades faster in the natural environment and puts less pressure on the ecosystem. According to environmental assessments, the use of this paper tape can reduce the environmental impact of packaging waste by 60%-70%, helping companies to fulfill their environmental responsibilities, reduce carbon footprints, meet social sustainable development requirements, and enhance their environmental image and market competitiveness.

White Kraft Butcher Paper Roll Application:

Electroplating industry

In the electroplating production line, White Kraft Butcher Paper Roll is a key isolation material and plays an irreplaceable role. During the electroplating process, metal workpieces need to go through a series of complex chemical treatment processes, including pickling, electroplating solution immersion, etc. At this time, the chemical corrosion resistance and isolation effect of White Kraft Butcher Paper Roll can effectively prevent adhesion between workpieces, avoid cross-contamination of the electroplating solution, and ensure that each workpiece can be plated evenly, thereby significantly improving the electroplating quality and production efficiency. Specifically, after using this paper tape, the high-quality product rate of electroplating companies can be increased by 25% - 30%, and production costs can be effectively controlled. For example, an electroplating plant used White Kraft Butcher Paper Roll for isolation when chrome-plating automotive parts. The results showed that the adhesion and uniformity of the coating were significantly improved, the surface finish of the product was improved by 40%, and customer satisfaction was greatly improved. At the same time, due to the stable performance of the paper tape, production failures caused by isolation material problems were reduced, the utilization rate of equipment was increased by 30%, the overall production cycle was shortened, and the economic benefits of the enterprise were significantly enhanced.

Stamping Industry

In the field of metal stamping, White Kraft Butcher Paper Roll is an important assistant to ensure product quality and production efficiency. During the stamping process, the workpiece is subjected to great pressure and impact, and its shape and surface are easily damaged. The high strength, high flexibility and folding resistance of the paper tape enable it to remain intact during the stamping operation, providing stable isolation protection for the workpiece. Practical applications have shown that the surface scratches and deformation rates of stamped parts isolated with White Kraft Butcher Paper Roll are reduced by 35% - 45%, and the dimensional accuracy and appearance quality are significantly improved. For example, a metal products factory used White Kraft Butcher Paper Roll for isolation when stamping electronic equipment housings. The results showed that the surface quality of the stamped parts was significantly improved, the defective rate was reduced by 40%, and the production efficiency was increased by 25%. In addition, due to the good flexibility of the paper tape, it can fit the complex shape of the workpiece tightly, making the production of some special-shaped parts easier and more efficient. According to feedback from the company, after using the paper tape, not only the product quality has been well received by customers, but also more orders have been won with high-quality products in the fierce market competition, and the market share has expanded by 15%.

Electronic hardware industry

The electronic hardware industry has extremely high requirements for the protection of components and parts, and White Kraft Butcher Paper Roll plays a key role in interlayer isolation in this field. During the production and transportation of electronic components and hardware parts, these precision parts are susceptible to physical damage and electrostatic interference. The flexibility and moisture absorption properties of White Kraft Butcher Paper Roll can effectively absorb vibrations, reduce collisions between components, and prevent the impact of humid environments on the performance of electronic components. After using this paper tape, the component damage rate of electronic hardware companies has been reduced by 40% - 50%, and customer satisfaction with product quality has been significantly improved. For example, an electronic manufacturing company used White Kraft Butcher Paper Roll for interlayer isolation when producing high-precision circuit boards. The results showed that the damage rate of electronic components on circuit boards during production, transportation and storage was greatly reduced, the production yield rate was increased by 35%, and the economic benefits of the company were significantly improved. In addition, due to the good isolation effect of the paper tape, the after-sales repair costs caused by component damage were also reduced, and the comprehensive competitiveness of the company was enhanced.

Printing and packaging industry

In the field of printing and packaging, White Kraft Butcher Paper Roll is an ideal choice for improving printing quality and packaging efficiency. During the printing process, paper and finished products are prone to adhesion, wrinkles and other problems, which affect printing quality and delivery efficiency. The isolation effect of this paper tape can effectively solve these problems, ensuring that the surface of the printed matter is smooth, the color is bright, and there is no adhesion and pollution. Customized width and thickness of paper tape can adapt to printed matters of different sizes and improve packaging efficiency. For example, a printing company used White Kraft Butcher Paper Roll for isolation packaging when printing high-quality picture albums. It was found that the printing quality of the picture album was significantly improved, the defective rate was reduced by 60% - 70%, and the packaging cost was reduced by 15% - 20%. At the same time, due to the good moisture absorption performance of the paper tape, it can effectively prevent the printed matter from being deformed by moisture, making the storage and transportation of the product more convenient, and the company's customer satisfaction and market share have been improved.

Machinery manufacturing industry

During the machinery manufacturing process, the processing and assembly of parts require a high degree of precision and protection. White Kraft Butcher Paper Roll can be used to isolate various mechanical parts to prevent collisions, scratches and rust during storage and transportation. Its hygroscopic properties can also effectively control the humidity of the environment and reduce the risk of parts getting damp and rusting. Machinery manufacturing companies that use this paper tape have reported that the damage rate of parts has been reduced by 30% - 35%, the downtime of processing equipment has been reduced, the production plan has been smoothly implemented, and the overall operational efficiency of the company has been optimized.

Warehousing and logistics industry

In the warehousing and logistics link, White Kraft Butcher Paper Roll provides a reliable isolation solution for the storage and transportation of goods. It can be used to isolate different batches and types of goods to prevent confusion and cross-contamination. In a high-humidity storage environment, the hygroscopic properties of the paper tape can protect the goods from moisture and ensure the quality of the goods. After using this paper tape, logistics companies have reduced the loss rate of goods by 20% - 25%, improved the traceability and management efficiency of goods, and significantly improved customer recognition of the quality of logistics services.

White Kraft Butcher Paper Roll Maintenance:

1. Storage environment control

To ensure the performance and service life of White Kraft Butcher Paper Roll, it should be stored in a dry, ventilated environment, away from moisture and direct sunlight. The ideal storage humidity is 40% - 60% RH and the temperature is 15 - 25℃. In such an environment, the paper tape can maintain the stability of its physical properties and prevent strength loss and mildew caused by excessive humidity. For example, in the warehouse, the paper tape should be stored on the shelf to avoid direct contact with the ground to reduce the impact of ground moisture. Regularly check the temperature and humidity of the storage environment and take appropriate moisture-proof measures, such as placing desiccant, which can effectively extend the shelf life of the paper tape and ensure that its performance during use is not affected.

2. Avoid contact with sharp objects

When handling and using White Kraft Butcher Paper Roll, try to avoid contact with sharp objects to prevent scratches or punctures of the paper tape. During storage and transportation, ensure that the paper tape roll is placed on a stable surface to avoid being squeezed or collided with other objects. If the surface of the paper tape is scratched or damaged, its isolation effect and tensile strength will be reduced, affecting the use effect. For example, in the warehouse, the paper tape roll should be placed on a dedicated shelf and separated by a protective pad to avoid direct contact with other hard objects. During use, the operator should be careful to handle it with care to avoid unnecessary damage to ensure the integrity and reliability of the paper tape.

3. Reasonable control of tension

When using White Kraft Butcher Paper Roll for isolation and packaging, the tension of the paper tape should be reasonably controlled to avoid excessive stretching or insufficient tension. The recommended tension range is 50 - 150 N, and the specific tension should be adjusted according to the characteristics and weight of the isolated items. Excessive stretching may cause the paper tape to break or lose elasticity, while insufficient tension cannot provide sufficient isolation and fixation effects, causing the items to loosen. For example, when packaging heavier industrial parts, the tension should be appropriately increased, but it should not exceed 70% of the maximum tensile strength of the paper tape; for lighter items, the tension can be appropriately reduced. By reasonably controlling the tension, the performance of the paper tape can be fully utilized to ensure the safety of the items during transportation and storage.

4. Regularly check the appearance quality

Before and during use, the appearance quality of White Kraft Butcher Paper Roll should be regularly checked, including whether there are scratches, wrinkles, holes and other defects on the surface. If any problems are found, the paper tape should be replaced in time to avoid using products with quality problems. For example, before each use, the operator should quickly visually check the surface of the paper tape roll. If obvious scratches or damage are found, the use should be stopped immediately and replaced with a new paper tape. Regularly checking the appearance quality can effectively prevent packaging failures caused by paper tape quality problems, ensure that each batch of isolation and packaging operations can achieve the expected results, and improve the overall production quality.

5. Correct use and operation

When using White Kraft Butcher Paper Roll, isolation and packaging should be carried out in accordance with the correct operating methods. Avoid applying excessive pressure or tension on the paper tape to avoid damaging the paper tape. When winding the paper tape, uniform tension and appropriate overlap should be maintained to ensure isolation effect. For example, when performing interlayer isolation, the overlap of the paper tape should be controlled at 10% - 15% to ensure good isolation effect while avoiding material waste. Correct operation methods can maximize the performance of paper tape, extend its service life and improve work efficiency.

6. Avoid long-term load bearing

Although White Kraft Butcher Paper Roll has high strength and flexibility, it should avoid long-term excessive weight or tension during use. Long-term load bearing may cause the paper tape to creep, gradually lose some strength and elasticity, and increase the risk of breakage. For example, in a storage environment, the use scenarios of paper tapes should be reasonably planned to avoid a single paper tape being subjected to a load exceeding 80% of its rated strength. For items stored for a long time, it is recommended to check the condition of the paper tape regularly and, if necessary, readjust the tension or replace the paper tape to ensure the safety and stability of the items.

White Kraft Butcher Paper Roll FAQs:

Is it possible to alter the dimensions of the White Kraft Butcher Paper Roll?

The size of White Kraft Butcher Paper Roll can be customized. The specific widths, lengths, and thicknesses of the material can be tailored to meet client specifications. You may send in your size requirements, and we will develop a quotation based on your needs.

Is White Kraft Butcher Paper Roll suitable for heavy-duty industrial applications?

Yes, the White Kraft Butcher Paper Roll has a high tensile strength and ts tearing strength makes it best suited for heavy industrial applications. It is extensively used for these applications in the field of electroplating, stamping, electronics, and hardware packaging and it helps protect the various components while in transit and other processing stages.

How should I store White Kraft Butcher Paper Roll to maintain its quality?

White Kraft Butcher Paper Roll should be kept in a clean and dry environment free from moisture and direct sunlight. They should also be kept away from vertical surfaces to prevent rolling which causes the paper to crease.