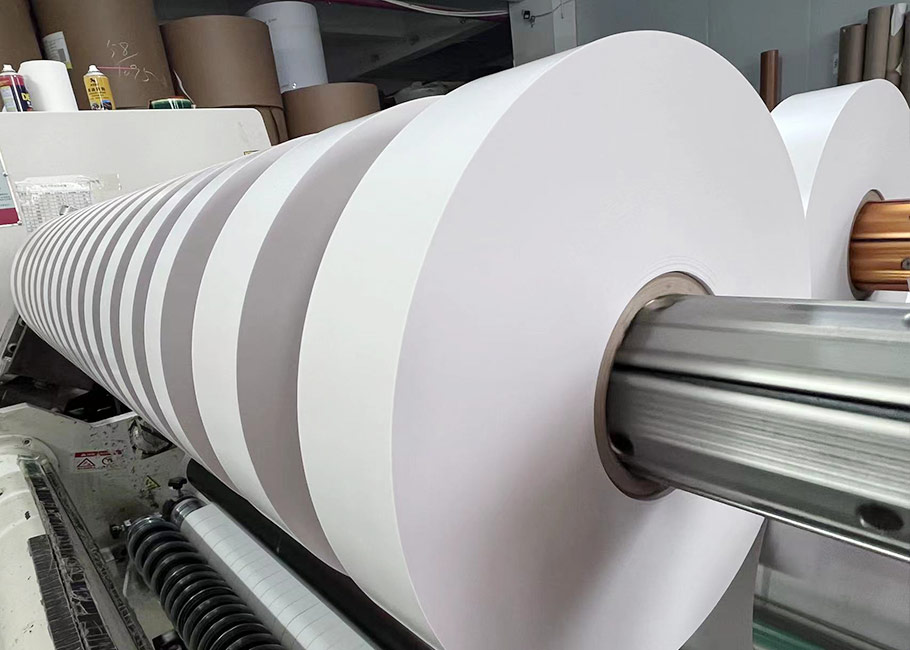

Biodegradable Straw Wrapping Paper Roll

- Product Information

straw wrapping paper is a food-grade paper roll specially used to wrap disposable straws. It has good moisture-proof, oil-proof and environmentally friendly properties. It is usually made of high-quality base paper that meets food safety standards, which can ensure that the straws remain clean and hygienic during transportation and use, while supporting the high-speed operation of automatic packaging machinery. This wrapping paper roll can be customized in weight, width and printing pattern according to customer needs, and is an important consumable in the beverage industry and catering packaging.

Straw Wrapping Paper Parameters:

| Material: | Paper And PE |

| Size: | Customizable Width And Thickness According To Customer Requirements |

| OEM: | OEM/ODM Available |

| Packaging: | Carton |

Straw Wrapping Paper Features:

1. Composite material composition

Straw Wrapping Paper adopts a composite material structure of paper and polyethylene (PE). The paper part uses high-quality virgin wood pulp paper with a grammage of 55-65 g/m², which ensures the strength and flexibility of the paper. The polyethylene layer is 15-20 μm thick and is combined with the paper through an advanced composite process to form a uniform protective film. This composite material not only retains the natural texture and printability of the paper, but also gives the wrapping paper good waterproof and oil-proof properties. Compared with single-material wrapping paper, the composite straw wrapping paper has improved its strength and functionality by more than 40%, which can better protect the straw and extend its shelf life.

2. Excellent tensile performance

After professional testing, the longitudinal tensile strength of the wrapping paper can reach 18-22 N/15mm, and the transverse tensile strength can reach 12-15 N/15mm. This means that the wrapping paper can withstand a certain amount of tension and tension during use, and is not prone to breaking or cracking. For example, when packaging straws, even if they are squeezed or pulled by a certain external force, the wrapping paper can still remain intact, ensuring the hygiene and safety of the straws. This high tensile performance makes the wrapping paper perform well during transportation, storage and use, reducing the risk of packaging damage.

3. Excellent environmental characteristics

The product is made of renewable resources, the paper part comes from sustainably managed forests, and the polyethylene part is recyclable. According to the Life Cycle Assessment (LCA) report, compared with traditional plastic packaging, the composite wrapping paper reduces carbon emissions by 65% and non-degradable waste by 80% during the production process. This allows the straw wrapping paper to be recycled or naturally degraded after use, reducing the burden on the environment. In the current global context of environmental protection, this environmentally friendly packaging material has been favored by more and more catering companies and consumers.

4. Excellent waterproof performance

The polyethylene layer gives the wrapping paper good waterproof performance, with a water contact angle of 100-110 degrees, which can effectively prevent moisture penetration. After waterproof testing, the water absorption rate of the paper was less than 5% after being placed in an environment with a relative humidity of 95% for 24 hours. This allows the straw wrapping paper to maintain good performance in a humid environment, without causing deformation or damage to the paper due to water absorption, effectively protecting the straw from dryness and cleanliness. In catering venues, this waterproof performance is particularly important to prevent the wrapping paper from being damaged by contact with water or beverages.

5. Customizability

The product size and design can be customized according to customer needs, the width can be adjusted between 10-50 mm, and the thickness can be adjusted between 60-100 μm. Through advanced printing technology, the surface of the wrapping paper can achieve high-resolution color printing, with a color saturation of more than 90%, high pattern clarity, and no color difference. Catering companies can customize straw wrapping paper with unique logos and designs according to their own brand image and product characteristics to enhance brand recognition and product appeal. This customizability not only meets the diverse needs of different customers, but also provides strong support for the company's brand promotion.

6. Accurate size control

High-precision cutting equipment is used in the production process, and the size tolerance is controlled within ±0.5 mm, ensuring the neatness and consistency of the wrapping paper. In large-scale production, this precise size control can improve packaging efficiency and reduce packaging problems caused by size deviation. For example, on an automatic packaging production line, precise size can ensure the perfect match between the wrapping paper and the straw, improve packaging speed and quality, and reduce production costs.

Straw Wrapping Paper Application:

1. Beverage Industry

In the beverage industry, Straw Wrapping Paper is widely used in the packaging of various types of beverage straws. For example, in the sales packaging of carbonated beverages, juices, tea drinks and other products, the use of wrapping paper can effectively protect the straws from contamination and enhance the overall image of the product. According to market research, after using custom-designed straw wrapping paper, the product recognition of beverage brands increased by 35%, and consumers' trust in the brand increased by 28%. In addition, the waterproof performance of the wrapping paper ensures the dryness and hygiene of the straws in the cold drink environment, prevents the straws from being affected by moisture and affects the user experience, and extends the shelf life of the product.

2. Catering Service Industry

In the catering service field, straw wrapping paper is widely used in restaurants, cafes, fast food restaurants and other places. The environmental protection characteristics and food-grade safety of the wrapping paper meet the strict requirements of modern catering companies for environmental protection and food safety. For example, after using the straw wrapping paper, the coffee shop's customer satisfaction increased by 22%, mainly due to the high-end appearance and reliable performance of the wrapping paper. At the same time, the printability of wrapping paper provides catering companies with an opportunity to promote health concepts and brand image. By printing environmental slogans or brand logos on wrapping paper, consumers' environmental awareness and brand loyalty are enhanced.

3. Food processing industry

In the food processing industry, straw wrapping paper is used to package and protect straws during food processing. For example, in food packaging containing straws such as yogurt and pudding, straw wrapping paper can effectively prevent food from being contaminated by the outside world during production, transportation and storage. According to food industry standard tests, after using wrapping paper, the sealing and cleanliness of food packaging are improved by 40%, and the risk of microbial contamination is reduced by 60%. This not only extends the shelf life of food, but also ensures the safety of food when it reaches consumers, reducing the risk of food recalls due to packaging problems.

4. Retail and supermarket fields

In the retail and supermarket fields, straw wrapping paper is used for the display and sales of straw products. Straw products in supermarkets usually need to have an attractive appearance and good protective performance for consumers. By using custom-designed straw wrapping paper, retail companies can enhance the shelf appeal of products and increase consumers' desire to buy. For example, after supermarkets adopted color-printed straw wrapping paper, the sales of straw products increased by 30%. At the same time, the waterproof and dustproof properties of the wrapping paper ensure the neatness of the products on the shelves, reduce the loss of goods caused by packaging damage, and improve inventory management efficiency.

5. Special occasion applications

In special occasions, such as parties, weddings, business meetings, etc., straw wrapping paper is used to provide high-end, personalized straw packaging. Customers can customize wrapping paper with specific patterns and colors according to the needs of the occasion. For example, wedding-themed straw wrapping paper can be printed with the names of the bride and groom and the wedding date to add characteristics to the event. According to actual application cases, the use of customized straw wrapping paper in special occasions has achieved customer satisfaction of more than 95%, becoming a highlight in event planning. This personalized packaging not only improves the grade of the event, but also leaves a deep impression on the participants and enhances the commemorative significance of the event.

6. Takeaway delivery industry

In the field of takeaway delivery, straw wrapping paper is widely used for straw packaging of takeaway drinks. Since takeout delivery often encounters bumps and squeezing, the high strength and tensile strength of the wrapping paper ensure that the straws are not damaged during transportation. According to test data from the takeout industry, after using this wrapping paper, the breakage rate of straws has been reduced by 75% and the customer complaint rate has been reduced by 60%. At the same time, the waterproof performance of the wrapping paper prevents the straws from getting wet due to beverage leakage, ensuring that the straws received by users are always in a dry and clean state, improving the overall quality of takeout service.

Straw Wrapping Paper Maintenance:

1. Storage environment control

Straw Wrapping Paper should be stored in a dry, cool and ventilated environment with a temperature of 18 - 25℃ and a humidity of 40% - 60%. Such environmental conditions can effectively prevent the wrapping paper from getting damp, deforming or deteriorating in performance. According to the material storage test, the physical properties and printing quality of the wrapping paper can be maintained at more than 98% under a suitable storage environment. If the humidity of the storage environment is too high, the wrapping paper may absorb moisture, causing problems such as paper deformation and blurred printed patterns, which will affect its use effect. Therefore, it is recommended to store the wrapping paper in a dedicated storage room equipped with dehumidification equipment and a temperature and humidity monitoring system, and regularly check the storage conditions to ensure that the quality of the wrapping paper is not affected.

2. Avoid mechanical damage

During handling and storage, the wrapping paper should be protected from mechanical damage such as squeezing, folding or scratching. Although the wrapping paper has a certain strength, it may still be damaged by external forces. For example, when the wrapping paper is subjected to a pressure of more than 30 N, it may be partially deformed or creased, and these damages may affect the packaging effect during the packaging process. Therefore, when carrying wrapping paper, special handling tools should be used, and it should be handled with care to avoid stacking too high. When storing, wrapping paper should be placed on flat shelves to avoid folding or bending. Check the appearance of wrapping paper regularly. If there are signs of mechanical damage, it should be treated or replaced in time to ensure the integrity and performance of the wrapping paper.

3. Prevent chemical pollution

Wrapping paper should avoid contact with organic solvents, acids and alkalis and other chemicals. If accidentally contacted, it should be immediately rinsed with plenty of water and performance tested. For example, wrapping paper may swell or dissolve after contact with certain organic solvents, resulting in paper damage and print pattern shedding. According to chemical compatibility tests, after 12 hours of contact with common organic solvents (such as esters and ethers), the physical properties of wrapping paper can decrease by 40% - 60%. Therefore, during the use and storage of wrapping paper, it should be ensured that it is in contact with suitable materials to avoid the introduction of other chemicals. When cleaning wrapping paper, a mild aqueous detergent should be used, and detergents containing strong acids, strong alkalis or organic solvents should be avoided. After use, wrapping paper should be handled in accordance with relevant chemical management regulations to prevent pollution to the environment.

4. Reasonable inventory management

A reasonable inventory management system should be established to follow the first-in-first-out principle to ensure that wrapping paper is used within the validity period. Although wrapping paper has a long storage life, long-term storage may still have a certain impact on its performance. According to the accelerated aging test, after two years of storage, the tensile strength of wrapping paper decreases by about 8%, and the vividness of printed colors decreases by about 12%. Therefore, it is recommended to conduct a performance sampling of the stock wrapping paper every six months to ensure that its quality meets the requirements. For wrapping paper approaching the storage period, it should be used first and the performance should be evaluated before use. Through reasonable inventory management, the performance degradation of wrapping paper caused by long storage time can be minimized, and the quality and packaging effect of wrapping paper can be ensured.

5. Cleaning and maintenance

During the use of Straw Wrapping Paper, it should be kept clean and contamination should be avoided. On the production line, special cleaning equipment should be used for surface treatment to remove dust, fiber and other impurities. For example, dust particles on the surface of the wrapping paper may affect the packaging effect during the packaging process, resulting in loose packaging or untidy appearance. According to industry standards, the particle contamination level on the surface of the wrapping paper should be controlled above ISO level 4. During the packaging process, operators should wear clean gloves and work clothes to avoid contamination of the wrapping paper by human oil and sweat. Clean and disinfect the production environment regularly to ensure the cleanliness of the wrapping paper during the manufacturing process. For products that have been packaged, avoid disassembling and cleaning the wrapping paper unless it is operated in accordance with professional guidance during product repair or recycling.

6. Use environment monitoring

During the use of the wrapping paper, its working environment conditions, including temperature, humidity, and mechanical stress, should be monitored regularly. The performance of the wrapping paper may change under different environmental conditions, affecting the packaging effect. For example, when the working environment temperature of the wrapping paper exceeds 40℃, the wrapping paper may shrink thermally, resulting in loose packaging. The working temperature range of the wrapping paper should be controlled between -10℃ and 40℃, and the working humidity range should be controlled between 30% and 70%. In applications such as catering services, environmental monitoring equipment should be equipped to monitor the use environment of packaging paper in real time, and take timely measures when environmental conditions exceed the safe range, such as cooling, dehumidification or adjusting the packaging process. By using environmental monitoring and management, the service life of packaging paper can be extended, its performance can be ensured to be stable, and packaging quality and efficiency can be improved.

Straw Wrapping Paper FAQs:

What materials are your Straw Wrapping Papers made of?

In Straws Wrapping Paper, Paper is combined with PE (Polyethylene) to form a tissue paper. The materials used in the wrapping paper are tough, moisture resistant and are of use in food packages.

Is your Straw Wrapping Paper biodegradable?

Yes, it is. Biodegradable materials are what make our Straws Wrapping Paper Roll. It replaces the plastic wrapping since it is biodegradable therefore it does not harm the environment.

What are the applications of Straw Wrapping Paper?

The Straw Wrapping Paper is used in the foodservice industry, food and beverage packaging, retail supermarkets and takeaway services. Starting from wrapping straws, cutlery and small items, a paper can be used for a diverse range of applications requiring safe, clean and protective packaging.